Waste Conversion

Evolution of Integrated Solid Waste Management Systems Enhanced with Municipal Utilities and Green Energy Production

The integration of waste-to-energy (WTE) can help municipalities optimize the value of their renewable fuel, maximize the revenue stream for their community, optimize solid waste, and maximize synergies to do more with less—energy, staff, resources, equipment and infrastructure.

Paul L. Hauck, P.E.

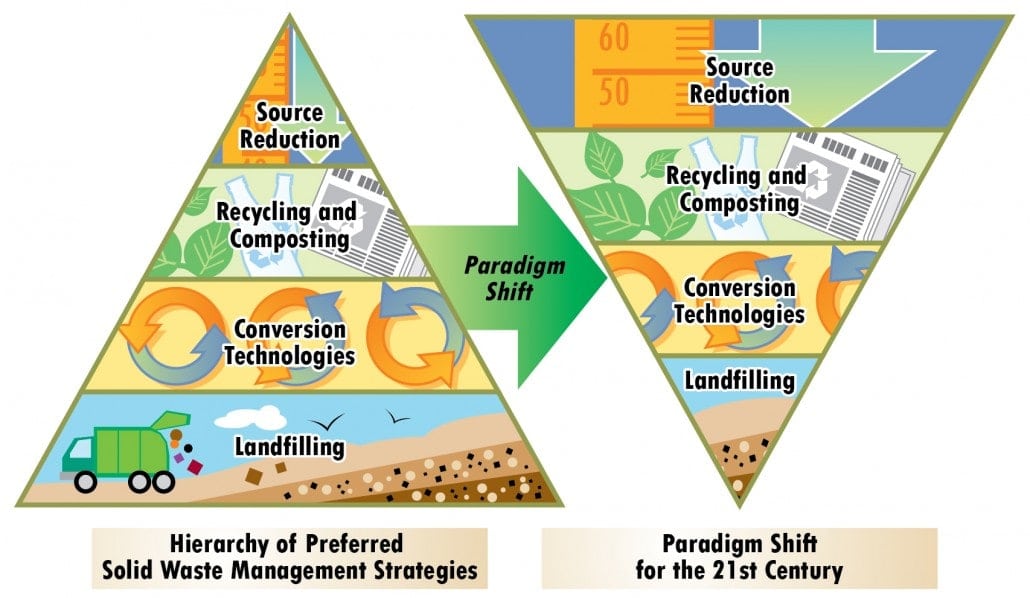

Much has changed over the past 40 years in the advancement of solid waste management. Early solid waste drivers focused on the top-down tiered approach promoted by the U.S. Environmental Protection Agency (EPA), which embraced a hierarchy of integrated waste management practices. These practices promote the following methods (in order of preference) to reduce, reuse, recycle and recover value from municipal wastes:

- Source reduction and reuse

- Recycling and composting

- Combustion with energy recovery

- Landfilling and incineration without energy recovery

The EPA-preferred strategy is illustrated below on the left side of Figure 1. This illustration depicts the state-of-the-art in the late 20th century with the bulk of the work performed by landfills. Advancing into the 21st century, the pyramid will soon be inverted to advance the goals of reducing the amount of wastes disposed of in landfills. This reduction will be achieved by implementing proven and emerging waste conversion technologies for production of renewable green energy. The use of this green energy may also be used internally, or “behind the meter,” for powering of other critical municipal services related to water resources.

There is a growing awareness across the United States that the inverted pyramid may not adequately address the true value of waste conversion technologies when viewed in a comprehensive approach based upon a life-cycle environmental and economic assessment. Specific local factors, which may significantly affect the life-cycle cost/benefit analysis, include: local recycling market conditions, specific waste material content and overall system costs associated with collection, processing, transportation and revenues derived from the sale of recyclables. Equally important are the affects of each alternative, including energy balance (consumption versus generation of energy), air and water emissions, and disposal requirements for process residuals. In summary, the following five emerging paradigms will affect the future evolution of solid waste management industry in the near future:

- Increasing landfill diversion and recycling goals

- Local, regional and national energy independence goals via clean renewable energy

- Growing awareness of sustainability and climate change initiatives

- Need for development of alternative water supplies

- Need for local sustainable economic development and high-quality jobs

Integrated Systems

Over the past 25 years, the public works department has been fractured into a multitude of specialty disciplines, including solid waste, recycling, water, wastewater, reclaimed water and stormwater. Most of the municipal electric utility systems have also been abandoned in favor of larger, investor-owned utilities. While each discipline has become more efficient and specialized, opportunities to take advantage of synergies between the various processes and municipal waste resources have not been realized. There are many benefits that can be realized through the integration public works departments within a centralized campus or network.

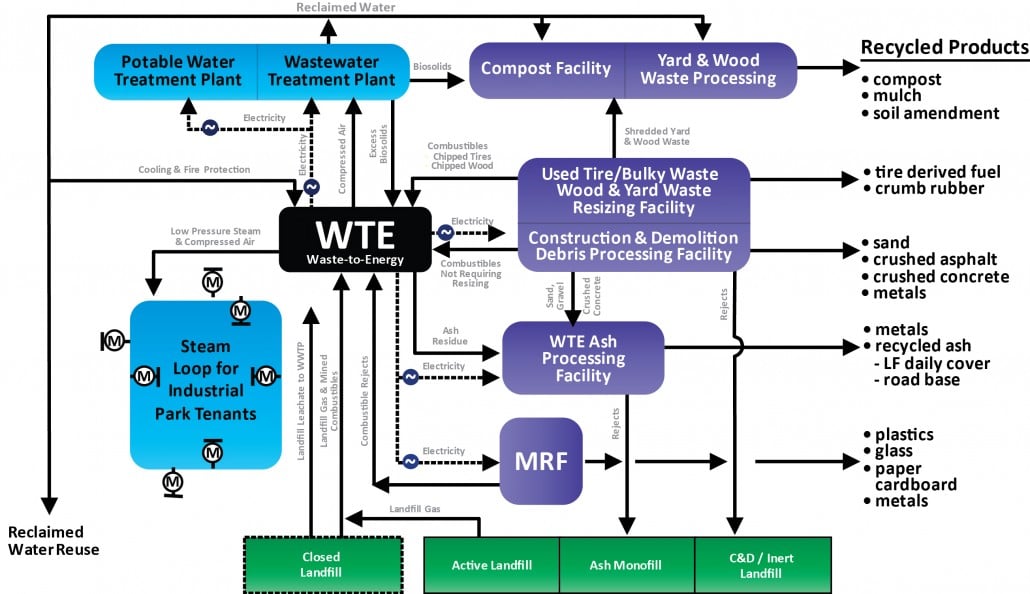

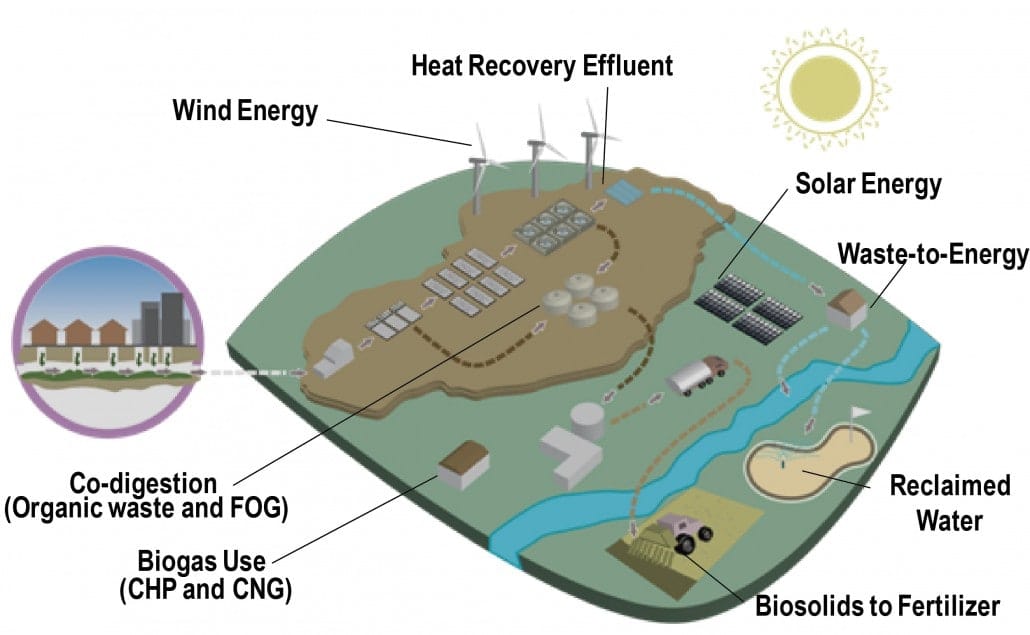

An integrated system using solid waste conversion technologies can provide a robust and flexible system to meet the seasonal variations in the system and take advantage of local market conditions. Figure 2 provides an example of numerous processes that could be integrated to manage various recycling, waste conversion and waste disposal processes, along with the option to use the renewable electricity for water and wastewater treatment.

The integration of WTE and water treatment processes as part of a municipal utility campus may be well suited to attract future incentives in the form of federally supported grants and/or loan guarantee programs. Successfully integrated municipal utility projects may also become role models for numerous urban U.S. communities.

Waste Conversion Technologies

Proven waste conversion technologies are considered to be those that have been successfully implemented on a commercial basis for more than 3 years. The following conversion technologies have had successful commercial experience with U.S. municipal feedstock wastes:

- Source separated biomass/yard waste composting

- Advanced massburn combustion WTE for production of steam and electricity

- Refuse derived fuel (RDF) combustion WTE for production of steam and electricity

- Landfill gas to energy (LFGTE) for production of electricity

The short list of promising emerging waste conversion to energy technologies includes:

- Thermal and plasma gasification/vitrification WTE for production of electricity and/or biofuels

- Catalytic depolymerization for production of liquid fuels

- Anaerobic digestion/co-digestion for production of biomethane

Several of the above noted emerging waste conversion technologies are currently in various stages of process/project development, but none are yet in commercial operation processing U.S. waste streams. Nevertheless, they may become viable over time and could be easily integrated into a community’s solid waste management system; thus, they should be closely monitored.

The average gross and net electrical power generation of WTE facilities has increased over the past decade. Approximately 550 kWh/ton of electricity can be generated (net) per ton of waste processed and sold to the local electric grid. Processing municipal solid waste (MSW) in a mass burn WTE facility typically results in a 90-percent volume reduction and 75-percent weight reduction of the processed MSW, thereby significantly reducing the volume of landfill space required for disposal.

Thermal Gasification Technologies

Although waste combustion technology has continued to advance over the past decades, various alternate thermal technologies are being promoted by many developers. These emerging thermal processes include pyrolysis and several forms of gasification (thermal and plasma, with or without vitrification). Some of these new or emerging technologies may merit consideration as viable candidates for integration into a community’s solid waste management system.

Thermal gasification processes are typically performed at high temperatures with a controlled amount of oxygen and/or steam, whereas pyrolysis is typically performed at lower temperatures in the absence of oxygen. Gasification and pyrolysis involve the application of heat or partial oxidation (with air or oxygen) to convert organic matter to a “synthesis gas” (syngas), which consists primarily of carbon monoxide (CO) and hydrogen (H2). The heating value of synthesis gas varies between 200 and 500 BTU/cubic foot, half or less the value of natural gas. The advantage to this process is that multiple opportunities exist for use of produced syngas to generate heat, power, pipeline quality gas or a wide variety of chemicals and liquid fuels. Efforts to date have primarily focused on gasification with oxygen, air, or steam, producing a syngas primarily consisting of H2, CO, and CO2. Syngas can be used in high-efficiency gas turbines for power production, or converted into a variety of gaseous or liquid fuel products. Gasification technologies are expected to be commercial within the next 10 years, given sufficient research and development.

Gasification technologies may also provide opportunities for sale of syngas to the natural gas markets or “across the fence” opportunities to local industries. The syngas can be used in a variety of industrial applications as a gaseous fuel for combustion and steam generation. Syngas can also be used as substitute/supplemental natural gas type fuel used for electric power production via gas turbine engines and fuel cells in the near future.

Renewable Electricity

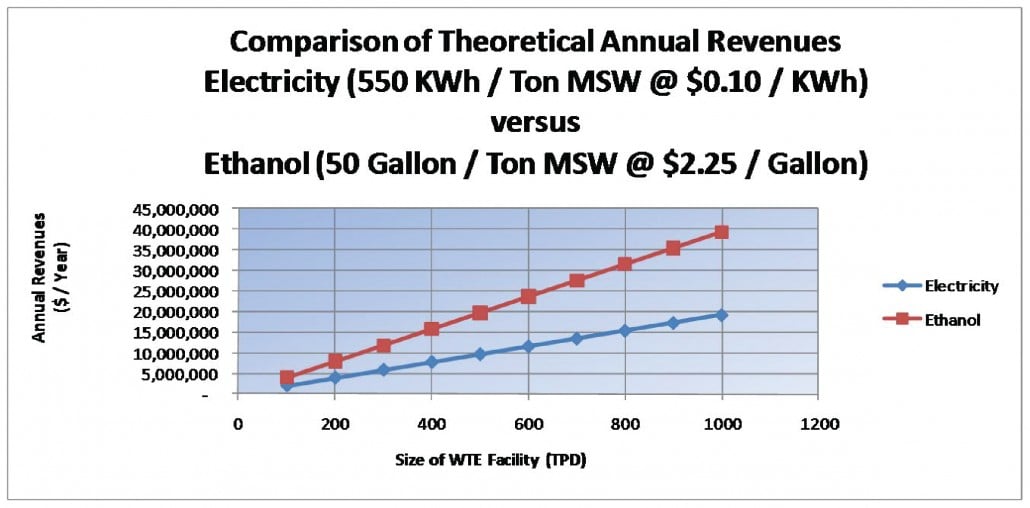

The overall market for renewable electricity is large, but the recent trend for power purchase contracts has shown a gradual reduction in the prices offered for electricity generated from WTE. This has been a result of several reasons, but it is primarily due to the “avoided cost” methodology by which investor-owned utilities set the price for purchased power. On a more promising note, the U.S. market for liquid fuels is also large, and may be a more lucrative route once waste-to-biofuel technologies have been successfully demonstrated on a commercial scale. Figure 3 illustrates the difference in project revenues for waste conversion processes, which produce electricity versus liquid transportation fuels (ethanol). Approximately twice the revenue stream can be generated by waste-to-biofuels compared to the traditional WTE technology.

While there is promise of higher revenues from the production of liquid and gaseous fuels compared to electricity, there are numerous hurdles to clear in securing the necessary long-term contracts for sale of renewable fuels at favorable economic terms and conditions. Liquid and gaseous fuel markets are heavily regulated with strict specifications for all potential suppliers before long-term favorable contracts would be negotiated. Additionally, the costs of production for biofuels from the conversion of syngas have yet to be determined, thereby complicating the potential for private financing of large multi-million dollar projects.

The U.S. Department of Energy recently awarded almost $600 million in grants and loan guarantees to 19 emerging bioenergy producers in December 2009 as a way to help develop the new bioenergy industry. Without federal grants and loan guarantees, few investors will be willing to commit to loans for unproven technology. Thus, it will take several years before these new bioenergy projects are operational and providing data on the technical and economic success of the various waste conversion technologies, many of which propose to use gasification technology for the production of syngas.

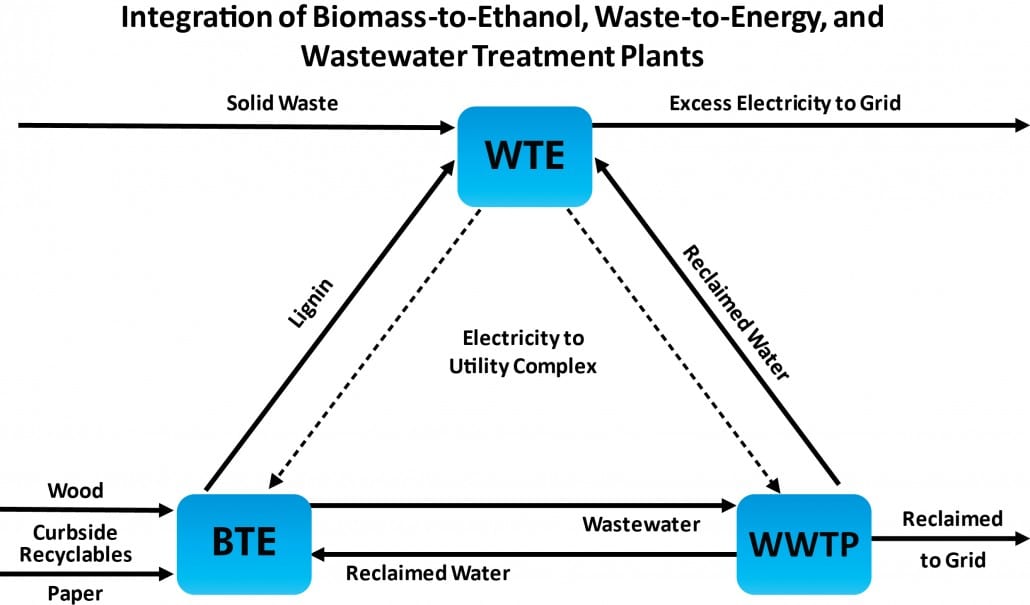

Regardless of the waste-to-biofuel technology used, the integration of a biomass-to-ethanol (BTE) facility into a municipal solid waste management system can result in a synergetic opportunity as illustrated in Figure 4. For communities that cannot find favorable rates for the sale of their renewable energy to the local grid, there is the option to use their own power internally, “behind the meter” for other vital municipal services. Examples include using electricity, steam and/or waste heat for:

- Treatment/pumping of water, wastewater, reclaimed water and stormwater resources

- Treatment of wastewater biosolids (e.g., drying, pelletizing)

- Operation of other recycling processes (e.g., material recycling facility (MRF), e-waste recycling, construction and demolition (C&Drecycling)

- Operation of municipal buildings (e.g., public works, city hall)

In this way, the municipality can maximize renewable energy value by avoiding the purchase of more expensive electricity from the local electric supply system. The transmission of electricity is often regulated by the local public service commission and may not be allowed unless the processes are contiguous, and under the same ownership. Issues that must be considered include the need and location of backup power supply, whether to stay connected to the local grid, or isolate from the grid.

Wastewater Treatment Plants

Wastewater treatment plants (WWTP) make perfect companions with WTE facilities. In addition to accepting the process wastewater (including cooling tower blowdown) from the WTE facility, the WWTP may also provide reclaimed water for use in the WTE facility for process water, cooling tower makeup, ash quenching and boiler water makeup systems (see Figure 5).

As a practical matter, most water and wastewater treatment plants have already been sited, and they are constrained to be located near sources or viable receiving waters, respectively. Locating a WTE facility adjacent to a WWTP may be more favorable for several reasons. WWTP facilities often have greater real estate available due to their need for buffers associated with mitigation of odors. They also typically have greater energy intensities and may allow more of the WTE electricity to be used internally, thereby maximizing the benefit to public works.

From a greenfield perspective, conventional water and wastewater treatment plants may not be ideal to use 100 percent of the electricity generated from a community’s WTE, assuming the WTE plant has been sized to process 100 percent of the available MSW. Most existing WTE facilities are not sized for 100 percent of the local MSW stream, due to a variety of reasons, including increases in population and waste generation rates occuring after WTE facility construction. In these cases, the size of the WTE facility could be tailored to match the demands of the water treatment systems, or the excess electricity may be simply sold to the local electric grid at the prevailing power purchase rate.

In the case of large urban areas with concentrated population centers, a new WTE facility may be sized to provide 100 percent of its electricity for operation of the existing water or wastewater facilities. When properly sized for the local water resource demands, the project can be designed for optimal performance in providing cost-effective services to both the solid waste and water resources departments.

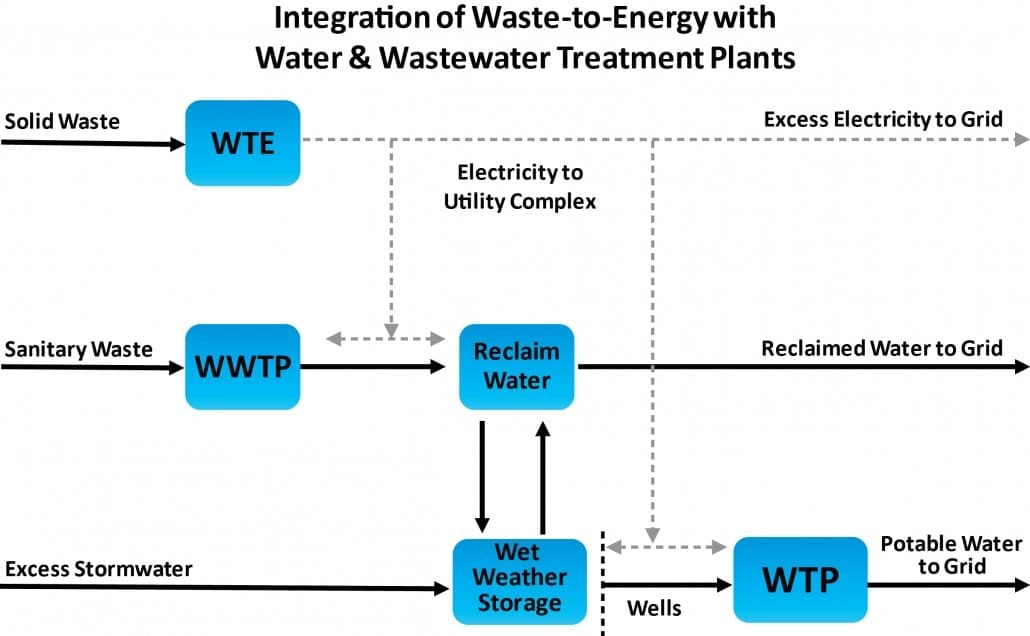

In the future , efficient municipal water resource and treatment systems may include reclaimed water distribution systems for irrigation; reservoir storage for reclaimed water and excess stormwater during wet seasons; and stormwater treatment systems to remove nutrients and pollutants per recent EPA discharge mandates. In such an arrangement, the demand for electricity and steam will increase significantly and provide opportunity for a properly sized WTE facility to provide all of the integrated campus needs. Figure 6 illustrates diagramatically how such a future water resource system and WTE facility could be integrated into a single utility campus.

The shared electrical savings that may result from the internal use of electricity warrants an evaluation of the various options suitable for each community. These benefits can be shared internally between the solid waste and water resource departments in any number of beneficial arrangements.

A Golden Opportunity

There are many concepts and opportunities that could be evaluated by municpalites who are willing to demonstrate leadership and environmental stewardship in the 21st century. The integration of proven and emerging waste conversion technolgoies with water resources is a golden opportunity to maximize the benefits and services to the local community, while minimizing costs . The integration of WTE with water resources can help municipalities optimize the value of their renewable fuel, maximize the revenue stream for their community by using the renewable power internally, optimize solid waste and water treatment systems for local demands to maximize synergies, and do more with less—energy, staff, resources, equipment and infrastructure.

Paul L. Hauck, P.E. is a senior environmental engineer forCDM (Tampa, FL). Over the past 38 years, he has worked in numerous industries, including commercial nuclear power, solid waste management, recycling and public works, along with two years developing a fuel ethanol project. Paul can be reached at (813) 281-2900 or via e-mail at [email protected].

Figure 1

Evolution of Solid Waste Management for the 21st century.

Figure 2

Solid waste management system with option to use power internally.

Figure 3

Comparison of revenues: electricity versus ethanol.

Figure 4

WTE integrated with wastewater treatment and biomass to ethanol processes.

Figure 5

Wastewater treatment plants as opportunities for resource centers.

Figure 6

Integration of WTE and water resources.

Figures courtesy of CDM.