How Bay Area Redwood is turning tree waste into green building materials to help solve the climate and housing crisis.

By Nick Harvey

In California, we face two concurrent crises—climate and housing—though, instead of worrying, this serves as a call to action to change the way we live in the built environment. The solid waste industry offers a novel and innovative solution to both problems by turning organic tree waste into hyper locally sourced timber products—a true green building material.

One of the myriad solutions to the housing crisis is through rezoning and upzoning—this is one of many tools to turn underused land parcels like office parks into thriving communities. The Bishop Ranch Office Park in San Ramon, CA is one example of an entire community that is transforming to address the housing crisis. Sunset Development’s vision includes turning parts of the Bishop Ranch Office Park it built and developed into a vibrant mixed-use transit-oriented district in partnership with the City of San Ramon to meet the Housing Element goals set forth by the state of California.

The standard development process sees the entire site razed; the best-case scenario is material from the project is recycled and reused. However, in many cases, several materials like trees removed from the site do not have adequate recycling pathways for their waste streams. In these cases, the materials can end up in the landfill.

Letting traditional building materials go to the landfill is the worst-case scenario. This is the very definition of an inefficient wasteful linear economy where raw materials are sourced from far corners of the Earth, manufactured into goods, then thrown away. Furthermore, there is embodied carbon created through this process from the transportation of raw materials to factories, then to distributors, and finally to construction sites, where it has been thrown away in conventional redevelopment. Worse yet, organic waste like trees removed from a construction jobsite release a significant amount of carbon into the environment if left to decompose into methane or burned at a cogeneration facility for energy. Recognizing this, the state of California passed the law SB1383, which aims to lower greenhouse gas emissions in the state by ensuring organic waste does not enter the landfill to meet ambitious GHG reduction goals.

A Streamlined Process

Until now, there has not been an effective streamlined process to use felled trees from construction job sites—it has been more convenient to follow a wasteful linear process. Bay Area Redwood (BAR) is innovating to fight against climate change and waste creation by turning tree waste into valuable resources. BAR has created a closed loop circular economic process to manufacture green building materials directly from what is conventionally considered waste from construction jobsites.

Let’s look at one example project. In January of 2023, BAR was contracted to remove and recycle 128 Ash, Redwood, and Sycamore trees from a development project in the heart of the Bishop Ranch Office Park in partnership with Sunset Development Company, Belmont Village, Anderson’s Tree Care Specialists Inc., and W.E.O’Neil Construction Company.

BAR and its partners accomplished this through implementation of source reduction upstream diversion techniques. Instead of seeing logs from the removed trees as waste as most demolition companies do, BAR views this as a valuable raw material. Subsequent material handling, saw-mill processing, and curing can extract further value. These raw materials that have conventionally been viewed as waste on a construction jobsite become locally sourced and manufactured timber products. Furthermore, using locally sourced green building materials reduces embodied carbon by minimizing transportation costs and keeping materials within a closed loop, thereby promoting a circular economy. An additional byproduct of creating materials within 10 miles of the jobsite is creating more jobs in the skilled trades.

Currently BAR is working with Belmont Village and WEO about incorporating these materials into furniture products to be used in the project opening Fall 2024. Currently BAR is working with Belmont Village and WEO about incorporating these materials into furniture products to be used in the project opening Fall 2024. “At W.E.O’Neil Construction, our projects often require pre-construction jobsite activities including the clearing of trees by demolition subcontractors. Our clients are interested in sustainability, but achieving this is always a moving target, Bay Area Redwood was a turnkey solution from tree removal to design and finished product delivering value at every step to the client, project, and environment,” says Rick Pomeroy, Project Director for W.E.O’Neil.

Moveover, another outlet for our locally sourced timber products, is in the BAR Showroom across the street from the project at the City Center Bishop Ranch, the lifestyle center developed as a modern square by Sunset Development Company. Sunset is clear in its vision to recreate the 21st century city—where mixed use residential, office, and retail come together—with a steadfast commitment to sustainability and local artisan businesses that give the City of San Ramon its character.

Turning Tree Waste into Timber Products

BAR’s mission is to divert tree waste from entering the waste stream. They turn tree waste into locally sourced timber products—true green building materials. Their vision is to see widespread implementation of circular-thinking principles applied to building material reuse throughout the world. Climate change will not be solved by doing one thing—it is a cataclysmic shift in the way we live.

Changing the status quo that relies on a linear economy is no easy feat, but this must be done to minimize the waste society produces as one tool to help solve climate change. BAR invests time educating and working with an interdisciplinary group across the supply chain, services sector, and local government to make this happen, including, the waste industry, policymakers, regional parks, construction, development, architecture and design,arborists, crane and rigging, earth movers and haulers, sawmills, millworkers, carpenters, and many other skilled and professional trades.

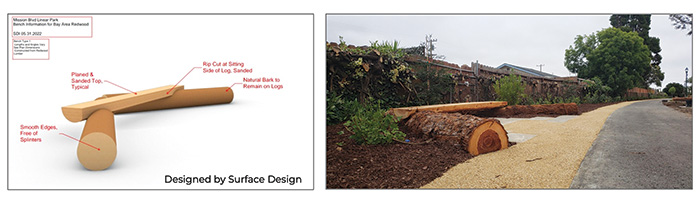

BAR partners with tree removal companies and developers to recycle trees that must come down. Once taken into the Livermore log recycling yard or San Ramon 13,000 sq. ft. warehouse, these logs are milled and processed into timber. Some tree species can be immediately cut and used for landscape projects, while other species have different material properties that can require curing for months to years. Subsequently, this material can be further processed to value-added goods by millworkers and carpenters into finished products like the tables and furniture in their City Center Bishop Ranch showroom.

While Bay Area Redwood was originally founded to recycle redwoods, they realized just how many tree species all around the Bay Area were entering the waste stream. They’ve grown to recycle cedars, pines, cypresses, oaks, walnuts, and many other local species to keep them out of the waste stream. They’ve even been innovating to find uses for unique species including the non-native blue gum eucalyptus, which many people say cannot be used. In 2021, BAR partnered with Lin King of UC Berkeley’s Cal Zero Waste Program, to divert more than 50 blue gum eucalyptus logs from entering the waste stream, which were felled as part of the Claremont Canyon Evacuation Support Project to make the Berkeley Hills more fire safe. These logs were turned into outdoor landscaping timber products including fencing, posts, and planter boxes. “Cal Zero Waste was excited to have the opportunity to work with Nick Harvey at BAR to research the possibility of repurposing our eucalyptus trees. This collaborative project involved our faculty, students, and staff to further support our campus zero waste goals,” Lin King, Zero Waste Manager, University of California, Facilities Services-Campus Operations, Cal Zero Waste.

Creating a Sustainable Society

Solving the climate and housing crises will not happen overnight nor will it be one solution—it will require many small changes and bringing together diverse stakeholders to work together in new and innovative ways. One small change is converting solid organic waste produced from the built environment into locally sourced timber products. Implementing upstream diversion source reduction practices and principles of circular thinking are the small changes needed to create a more sustainable society. | WA

Nick Harvey is the CEO and Founder of Bay Area Redwood. Nick has a B.S. in Chemistry and Biochemistry from the College of Creative Studies at UCSB. Prior to founding BAR, Nick was a staff Materials Chemist at Lawrence Livermore National Laboratory where he created new materials utilizing earth abundant elements. He can be reached at [email protected]. To partner on tree recycling, projects that could use recycled lumber or furniture, or to collaborate on implementing circular thinking, visit Instagram @BayAreaRedwood or the website at bayarearedwood.com.