EnBio MP from EnBio Industries achieves the highest level of efficiency possible and extends the equipment’s life as long as possible, while also being environmentally safe.

By Josh Green

There are many factors that make keeping hydraulic equipment from operating at peak performance a difficult task. This is especially true when the equipment is used in waste and recycling applications. It is made even more difficult when the equipment is poorly maintained. This was the case for a large national retail chain distribution center with a newly acquired Side-Eject Horizontal Baler. The baler had been moved from a sister facility that was being taken offline. The first reaction from the facility receiving the new baler was excitement for not having to spend the funds to purchase new equipment. That quickly changed once the baler arrived onsite.

Challenges

Once the maintenance team was able to perform a thorough inspection, it was clear that getting the baler up and running was not going to be as easy as flipping a switch. All of the hoses and filters were removed and replaced as each was filled with sludge and varnish buildup, debris, as well as what was believed to have been a grease product not correctly suited for the application. All of this made it clear that the baler’s entire hydraulic system was going to need to be taken apart and properly cleaned.

Once that thorough system cleaning took place, the baler was installed in its new home and hydraulic fluid needed to be selected. Another goal for the hydraulic fluid selected was that it would allow them to apply for an additional LEED Credit through the U.S. Green Business Council, helping to add points to the facility’s existing LEED certification.

Peak Performance

The organization decided on EnBio MP from EnBio Industries (Lake Worth, FL) based on the project goals—achieving the highest level of efficiency possible and extending the equipment’s life as long as possible, while also being environmentally safe. In order to reach the highest efficiency level from the system, a high-performance synthetic would be needed. EnBio’s base fluid not only had the highest lubricity of any hydraulic fluid class, but also dissolved the varnish and sludge left behind from the previous fluid. This allowed the baler to reach peak performance based on its current condition and also increase efficiency over time as old varnish dissolved and was removed from the system. This increase in efficiency decreased the workload on the equipment itself as well as lowered energy consumption, extending the life of individual equipment components and the baler.

Other important factors that played into the decision to use EnBio MP were greatly decreased equipment wear, a high viscosity index, no shearing, excellent oxidation stability, and longer service life. Additionally, a spill of EnBio MP could be washed away with water and would not stain the concrete if spilled. Because EnBio MP is readily biodegradable and has near zero toxicity, spilled fluid dissolves in water and can be washed directly into a standard drain.

Longevity

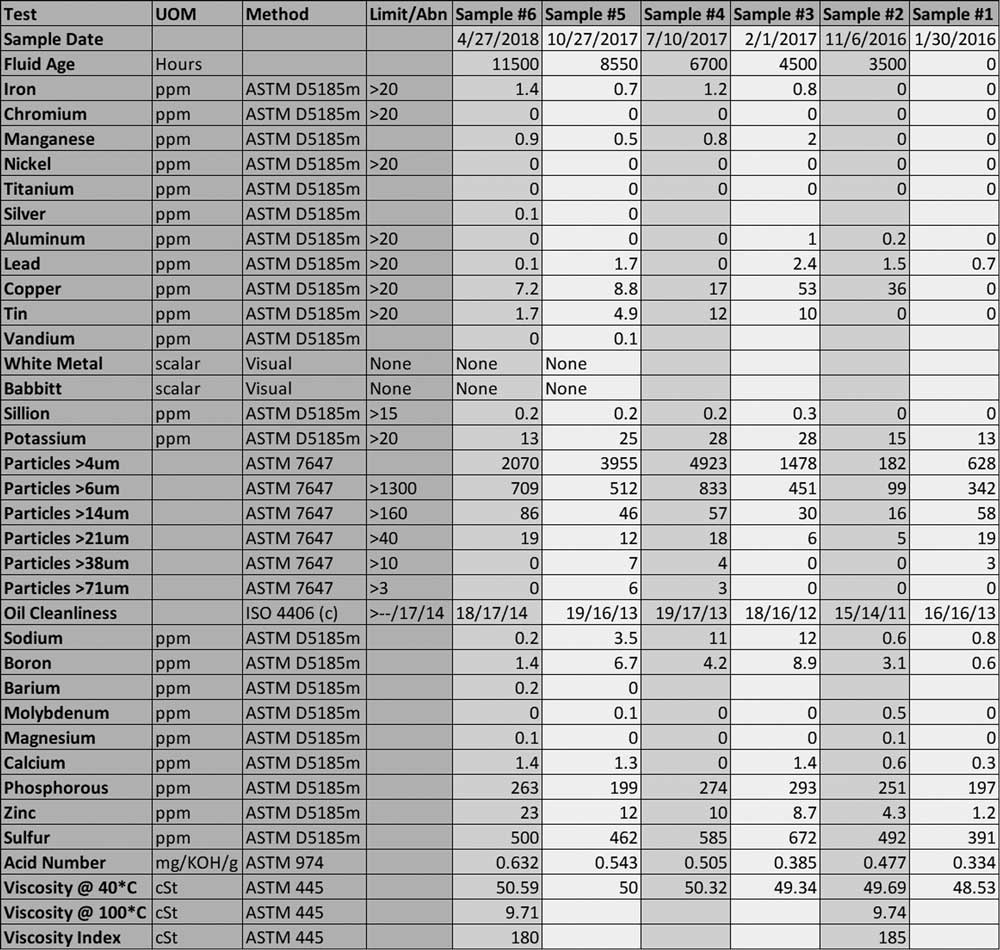

The baler was brought back online in January 2016 with an initial period of limited use as the new section of the facility was fully stocked and manned. EnBio MP has been able to continue to clean the system and increase efficiency, all while using the same fluid. As soon as the fluid was put in the system, over two and a half years ago, the cleaning nature of EnBio’s chemistry began to dissolve the sludge and varnish from the previously used products. The baler’s filter gradually picked up all of this material and it has been removed as filters are replaced about every six months. Once the buildup was fully dissolved, filter replacement was rolled back to an annual replacement schedule. Throughout this time, performance has remained consistent as viscosity has increased by only 9.5 percent—from 199 originally to 180 after 11,500 hours. Additionally, contaminants and heavy metals remain very low and fluid cleanliness has remained steady. The initial fluid is still in the baler and currently has almost 14,000 hours on it. There has never been a need to top up the fluid during the entire period of use.

The baler OEM recommends maintenance teams replace fluid on an annual basis. EnBio MP has gone well beyond that while maintaining high levels of performance and will continue to be used based on the latest sampling data. The current estimate for fluid life will be between 15,000 and 20,000 hours, which will amount to somewhere between a total of three and four years of operational use.

Figure 1 highlights the tremendous longevity of EnBio MP and how using EnBio MP has benefited the baler’s efficiency and expected lifetime as well as the continued cost savings. Increases in efficiency have reduced energy consumption, no sludge buildup and reduced wear has decreased component costs, and longer fluid life—with no equipment problems—which reduces maintenance costs. This has also led to an extended estimation for the life of the baler itself, amounting to significant overall savings. These benefits can be seen across all types of hydraulic systems and is why the retailer began this testing with the hopes to expand the use of EnBio MP to additional systems in their distribution facility.

The chart shows the consistency in performance of EnBio fluid over a two-year period.

Josh Green is Director of Business Development for EnBio Industries (Lake Worth, FL). He can be reached at [email protected]. For more information, visit www.enbiousa.com.