Using asset recovery software, asset recovery companies can improve their operational efficiency throughout their services.

By Henry Purchase

WEEE, or waste electrical and electronic equipment, is any discarded device with a cord, battery or plug. Sometimes referred to as e-waste, it includes old cell phones, laptops, televisions and more. WEEE can be harmful to humans and the environment because it contains toxic chemicals like lead and mercury. These chemicals can leach into the soil and groundwater if they are not disposed of properly.

Electronic waste, now more than ever, needs to be recovered and passed into the circular economy. In 2019, a record 53.6 million metric tons (Mt) of e-waste was generated, and only 17.4 percent of this was officially documented as formally collected and recycled.1

Much of this waste that is not correctly collected goes to landfills or is illegally exported to third world countries that process equipment to make money from the precious metals contained in WEEE. For example, in 2010, an estimated 201,600 people across Ghana, including families and children, depended on WEEE recycling and management for financial support.2 Despite this support, the high amount of toxic materials found in e-waste has caused extensive environmental damage in the country.

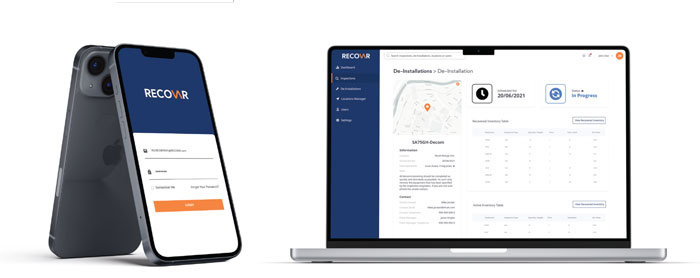

Image courtesy of RECOVAR.

What is Asset Recovery Software, and How Can it Help E-Waste Companies?

Asset recovery software is a type of software used to digitize the end-of-life supply chain for e-waste. Designed specifically for asset recovery companies and internal asset recovery programs, asset recovery software can provide the following functions:

• Client/source management and generation

• Site inspections/inventory audits—the best software will have an easy-to-use mobile application for this

• Offline capabilities (for inspecting or recovering equipment in rural areas or large data centers)

• Integration with ERP, spare part and warehouse management software

• Job scheduling for site engineers

• Location inventory management and integrated de-installation approval processes

• Analytics and reporting

With asset recovery software, asset recovery companies can follow standardized processes and collect digital audit trails needed to meet regulations and streamline operations. The benefits of the above capabilities are:

1. Increased revenue and volume of leads for sales teams

2. Standardized inspections eliminate time spent processing data, reducing costs

3. Reduced data loss in the field reduces the need to duplicate work, lowering your bottom line

4. Removing the need to manually input data reduces costs through automation

5. Eliminating paper trails saves managers time, allowing them to focus on revenue-generating activities

6. Integration and standardization make your customers feel at ease, increasing trust in your brand

7. Data provides the opportunity to increase revenue by allowing managers to prioritize the work that drives results

Right: Asset recovery software should provide a digitized audit trail of e-waste.

How Asset Recovery Tools are Revolutionizing the Way We Think About WEEE Disposal

The world is producing more and more WEEE every year, and it is a major environmental problem that needs addressing. Despite consumers and businesses being the source of many e-waste problems and, by law, must dispose of e-waste properly, they often do not prioritize their end-of-life equipment.

When it comes to disposing of WEEE, companies and consumers want a frictionless process. Whether by dealing with an asset recovery company or selling it directly, they want it to be quick and easy, all while making money and not paying for collection.

This is where asset recovery software comes in—making it easy for asset recovery companies and customers to value equipment and arrange jobs to the right engineers. Once collected, the equipment can then be processed into the circular economy.

Benefits of Asset Recovery Software and how it Can Improve Your Bottom Line

Asset recovery is slow and manual—often relying on unstandardized paper and Excel trails. This leads to frustrated managers who battle with dozens of Excel spreadsheets and

hundreds of images. Meanwhile, engineers rely on photos to provide proof of work.

Manual, repetitive and unstandardized work hurts your bottom line and frustrates your customers, who prioritize simplicity, convenience and financial return—the digital revolution has led to customers wanting things quicker and simpler than ever.

Asset recovery software can overcome these problems through a combination of digitization and automation. Consider the below three benefits of asset recovery software:

1. Reduced costs: Reducing the amount of manual or duplicated work and streamlining processes reduces costs as you need fewer resources to get the same amount of work done. For example, managers save time and money by deploying fewer engineers to the same job. Additionally, asset recovery software automates many tasks that managers find tedious.

2. Increased revenue: Only 17.4 percent of e-waste was officially documented as formally collected and recycled. From an asset recovery company’s perspective, the remaining 80 percent is untapped revenue. By making it easier for customers to give you what you need to complete jobs, sales revenues are increased.

3. Transparency: Paper and Excel trails are difficult to track and make gaining valuable insights or data difficult. Digitization allows for the analysis of workflows and jobs, allowing you to make data-driven decisions to improve processes. Furthermore, by digitizing workflows, you can get a complete audit trail of work—reducing risk and providing peace of mind to your customers.

Developing the Business Case for Asset Recovery Software

The growth in the e-waste recycling industry has led to the heightened importance of scalable and efficient asset recovery services. While it can be challenging to justify spending on

software to improve already profitable processes, remember the time and cost savings made from the investment can be directed into OPEX to drive future growth.

Asset recovery software can self-fund. By increasing leads and the volume of equipment recovered, you can generate returns that drive a positive ROI and solidify your competitive advantage. High returns for asset recovery companies leads to more profitable returns for customers. These returns lead to client loyalty, which compounds over time as positive reviews drive inbound leads.

Furthermore, standardized audit trails and processes reduce the risk of receiving fines for accidentally breaching WEEE regulations. While this risk may be slim, particularly for experienced organizations, WEEE compliance will only tighten over time in an ever-changing environment.

The Future of Asset Recovery Software

With asset recovery software now functioning on mobile phones, new capabilities can be used during the asset recovery process. For example, most smartphones have high-resolution cameras—the photos taken from these can be used to develop artificial intelligence and machine learning to automatically characterize e-waste—further speeding up the asset recovery process. AI can also be used to predict where and when customers will have equipment available for you to recover.

The e-waste industry is focused on gaining the most revenue from moving equipment into the circular economy. As the popularity and awareness for the circular economy increases, asset recovery software will evolve to provide more transparency around what happens after disposal—mapping the whole end-of-life supply chain. | WA

Henry Purchase is the Co-Founder and Managing Director of RECOVAR Ltd, a leading asset recovery software for the IT and telecommunications industry. He can be reached at +441633981226 or e-mail [email protected].

Or visit https://recovar.co.uk for more information.

Notes

www.itu.int/en/ITU-D/Environment/Pages/Spotlight/Global-Ewaste-Monitor-2020.aspx

www.ncbi.nlm.nih.gov/pmc/articles/PMC8392572/