Although maintenance challenges are universal, through the implementation of technology, fleet managers have the power to take control of the problem.

By Don Diego Padilla II

You can have the newest, top-of-the-line waste trucks in the industry, but they will also be the costliest if you are having to repair or replace parts. An effective preventative maintenance program and pre/post-trip inspection technology can help a fleet company save thousands annually. Taking action quickly and effectively before equipment fails is critical to meeting service levels and boosting operational/revenue generation performance. Preventative maintenance is so necessary to operational health that agencies are faced with continually changing contract policies and the industry is rich with new inventions and technologies.

The importance of taking action effectively before equipment fails is a critical step that has opened doors to several policy changes, new inventions and technologies. Unscheduled downtime creates a ripple effect and gets costly for businesses and frustrating for fleet managers.

Why You Need to Be Proactive About Fleet Maintenance

Preventative maintenance programs allow agencies to proactively take action prior to equipment failure. Committing to a preventative maintenance program helps solid waste management fleets keep their vehicles on the road, reduce unscheduled vehicle downtime and increase the productivity of vehicles and personnel. Properly maintained systems ensure fleet owners always have access to a 360° view of each vehicle, its environment and its operating conditions. Maintained systems also contribute to the ongoing safety of vehicle operators and others on the road.

Regular fleet maintenance helps catch problems early on, saving a company from what can end up being thousands of dollars in repairs or the replacement of truck parts. Additionally, fleets that use technology for insight into truck and driver performance are able to save anywhere from 10 to 20 percent on maintenance costs. Insight includes service history, preventative maintenance status, and warranty and truck build information—all of which help increase overall fleet safety,

efficiency and uptime.

Pre/Post Trip Inspections

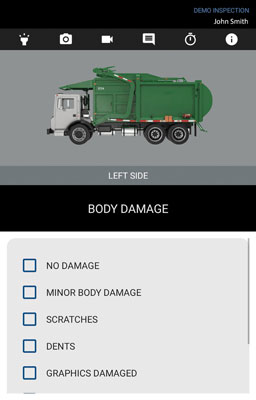

Regular inspections ensure truck equipment operates at 100 percent efficiency at all times. Automated vehicle inspection programs help eliminate manual inspections using paper forms and support a variety of inspection types for a more sophisticated inspection. This results in enhanced fleet maintenance and operational efficiency. Waste and recycling companies that use Android devices can download an App from the Google Play Store that enables automated trip inspections that can be customized specific to their operations. Digital inspection data is instantly available for maintenance, auditing and measuring results.

Images courtesy of Safe Fleet.

Bringing it all Together

The challenge is finding customized preventative maintenance programs that fit the needs of the waste and recycling industry as well as finding qualified technicians to diagnose and optimize truck performance based on trip inspection results.

A great Preventative Maintenance and Vehicle Inspection program helps relieve the stress of repair concerns, increases vehicle uptime and, by extension, improves service levels. PM tools help fleet managers have better control of their operations and respond to emergency situations quickly and effectively. Look for intuitive, easy-to-use, automated pre/post-trip inspection Apps that can be downloaded for Android devices from the Google Play Store. The vehicle inspection technology should be able to tightly integrate to your fleet maintenance system via open architecture and a public API, which can drive even more efficiencies such as advance parts ordering, labor planning and automated warranty considerations.

Finally, be sure that preventative maintenance is conducted by experts who specialize in fleet management systems, for rapid and streamlined repairs in order to ensure your fleet is optimized to provide best service to your customers at all times.

Prevention is Key

Minimizing the frequency of unplanned downtime with a preventative maintenance action plan before equipment failure can minimize the ripple effect. Protecting fleet equipment and parts is a top priority for every waste fleet manager. For several years now I have been witnessing and hearing costly stories; what I know is that the challenges are universal, but through the implementation of technology, fleet managers have the power to take control of the problem. It is about identifying potential issues before they become costly problems and fine-tuning your maintenance schedules. | WA

A waste industry fleet management veteran, Don Diego Padilla II is Vice President of Sales at FleetMind – a Safe Fleet brand, where he spearheads business and customer development activities. Safe Fleet is the largest fleet video supplier in North America with over six leading video surveillance brands and integrated fleet safety management technologies to help cities work smarter and stay safer. Previously, Don Diego was a Regional Sales Director for Allied Waste (Republic Services), a leading provider of solid waste collection, transfer, recycling and disposal services in the U.S. His industry white paper on fleet safety garnered a Network Products Guide Award in the “Best White Paper” category. Don Diego has been published in numerous industry magazines and is a frequent speaker at industry forums and regional municipal waste management events. He can be reached at (770) 876-4507 or e-mail [email protected].