With a wide range of vehicle and safety technologies available, video-based safety programs have emerged at the forefront, and many progressive waste and recycling fleets have realized the safety and cost benefits of the technology.

Jason Palmer

The waste and recycling industry is one of the most challenging in the U.S. Collection fleet vehicles frequently operate in congested and hazardous environments and face significant risks tied to collisions, personal injury and property damage. For these reasons, fleets approach managing risk and operating safely very seriously not only to ensure the safety of their employees and the general public, but also to reduce costs, fleet claims and litigation, while improving operational efficiency. Adding to the complexity of an already risky operating environment is new technology.

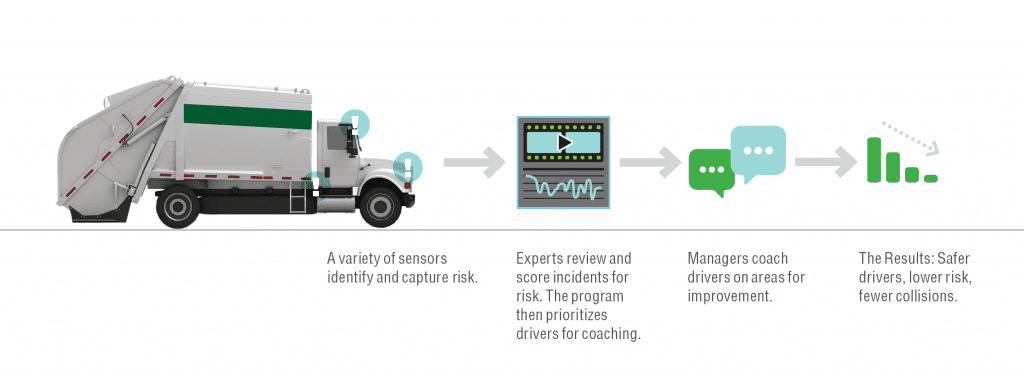

With a wide range of vehicle and safety technologies available, many fleets today take advantage of advanced solutions that help to prevent accidents and deliver additional operational benefits. Video-based safety programs have emerged at the forefront, and many progressive waste and recycling fleets have realized the safety and cost benefits of the technology. The combination of immediate video-based insights and transportation intelligence, which transforms massive volumes of data generated by fleets into real-time actionable information, provides fleets with predictive analysis and prescriptive actions, leading to significant business results.

Why Video?

Drivers represent the biggest opportunity to improve fleet safety and efficiency. Video-based safety systems offer the context, flexibility and insights that enable a host of benefits, from driver exoneration and improvements in driver performance, to compliance with standard operating procedures, improved customer service and even the identification of new revenue streams. Video provides valuable insight that traditional tabular “critical event” reports cannot, saving time and allowing for more effective driver coaching. As a result, fleets can reduce collision frequency, lower fuel consumption and bring drivers home safely.

Perhaps the most obvious rationale for adopting a video safety and analytics solution is driver exoneration. All too often, when fleet drivers are involved in an accident—whether minor or involving a fatality, assignment of blame comes down to “he said/she said.” In fact, many times, the truck driver is automatically assumed to be at fault. When this occurs, it can be difficult to know what really happened. With video, fleet managers know within minutes what actually transpired and can determine whether their driver was at fault. When not at fault, the driver can be exonerated quickly, preventing a costly claim or enabling the fleet to file a claim for damages. If the company driver is at fault, video enables virtually immediate knowledge of the circumstances, speeding the claim resolution process.

Because of their unique operational profiles, which may include backing or maneuvering in tight alleyways, collection fleets often require unique video-based safety system configurations. Most waste collection fleets leverage at least four cameras, providing 360-degree visibility in the cab and around the vehicle. The most advanced solutions allow for eight or 12 cameras. This added visibility is critical to the safety of waste collection employees, who operate near and around the vehicle throughout the day. For waste and recycling fleets in particular, multiple camera deployments can also help ensure compliance with standard operating procedures, such as confirming whether the driver stepped out of the cab prior to backing or used a spotter for backing assistance.

For improved customer service, captured video can support follow-up conversations with customers on occasions when waste containers are inaccessible due to a locked gate or another vehicle blocking the approach. Video has also proven valuable to fleets in uncovering additional revenue opportunities. Video of overflowing bins facilitates timely, relevant sales calls to clients to justify increasing the frequency of pickup.

Resource Magnifier

Keeping a fleet competitive requires continued focus on resources, managing both overhead and technology investments. As fleets expand, drivers, dispatchers and managers must collaborate in order to grow together in a way that achieves safety goals without increasing cost. Video can be an important resource that helps facilitate a productive conversation between coach and driver by clearly showing what happened.

When considering video-based safety options, it is important to choose recording capabilities that best align with specific fleet needs. Fleets can choose to only record if triggered by a G-force movement such as swerving, hard braking, collision, etc., or to record everything across all cameras. Continuous recording is helpful in that it provides a clear record of all activity and incidents, however this produces a mountain of video footage, most of which is not helpful in identifying potentially unsafe situations or employees who need to improve on certain skills. This is why the best configuration for most waste fleets is to have a robust exception-based video recording system combined with continuous recording.

The most advanced exception-based recording systems have a finely-tuned triggering mechanism that can detect if the vehicle is driving on the street, at the transfer station or in the landfill. Because these surfaces are extremely different, a G-force movement on one might be completely normal, whereas it could indicate an unsafe situation on another. Combining exception-based and continuous recording, areas of risk can be identified and addressed in a timely manner, and the full record of activity is available for reference when needed. Another option is to have video aligned with a fleet’s specific routes, enabling managers to quickly identify and access video associated with a customer location and time.

To optimize the value of an investment in video-based safety, fleets are wise to look for a managed service program—one with a team of experts reviewing, scoring and prioritizing events according to a consistent set of standards that focus on the risk areas that have the biggest impact on each fleet. By alleviating the fleet of the burden of extensive video review and analysis, these programs act as a resource magnifier—saving time while delivering results, and building a real and sustainable competitive advantage.

Coaching is key to the success of any video-based safety program. An intuitive coaching workflow, which is a critical component of a managed service solution, combined with easy-to-use tools, helps to ensure continual improvement and bottom line results. Together, these efforts ensure driver understanding and strengthen the relationship between drivers and managers, while speeding up the roll-out and adoption of the program, maximizing ongoing results.

Counteract Data Overload

Vehicles are loaded with sensors that deliver massive volumes of rich data. Add to this multiple new technologies and fleets can face data overload. By transforming data into insights that can be leveraged across the operation, fleets are able to discover new, untapped opportunities that materially improve efficiency and overall financial performance. When considering new technology, be sure it provides:

- Unbiased, contextual and actionable data—To benchmark performance and quickly isolate what is working and what is not

- Integrated performance management—To close the loop with safety, fuel and operational KPIs, measuring whether actions were taken and if they were effective

- Flexibility—To choose from prebuilt analytics or combine the vendor’s data feeds with proprietary fleet-owned data and other third-party data

- Interactive data visualizations and dashboards—To explore data at different levels in order to spot trends, identify opportunities and make data-driven decisions

Instead of drowning in big data, be sure you get value from your technology investments and shared intelligence across your fleet.

Jason Palmer is COO of SmartDrive Systems (San Diego, CA). Jason brings more than 25 years of leadership delivering products to market for fast-growing technology companies such as Qualcomm, Now Software, Epicor and WebTrends. In his career, he has also worked with many of the leaders in large-scale analytics initiatives including Microsoft, Yahoo, The New York Times and Knight Transportation. He is a member of the NWRA Safety Committee working with many of the leading waste fleets. Jason has been with SmartDrive more than 10 years, leading the development and delivery of SmartDrive’s market leading video-based safety programs and analytics. For more information, call (858) 225-5550 or (866) 447-5650 or e-mail [email protected].