In this review of a mined landfill, the types of materials, quantities, pollutant loading, risk, mode of entombment and costs are all considered, and the materials that were excavated and re-deposited are examined versus standards to be adopted in modern landfill mining.

Keiron Finney, Clive Roberts and Martin Dye

In the 2010s, landfill mining has become an increasingly attractive possibility and the recovery and re-use of previously disposed of wastes seems more and more likely. European initiatives are considering this subject along with wastes that are still deposited, even when recycling is a key part of the EU waste strategy. Future landfill mining would benefit from the experiences gained at sites that were mined in the UK in the 1990s. In this review of a mined landfill, the types of materials, quantities, pollutant loading, risk, mode of entombment and costs are all considered, and the materials that were excavated and re-deposited are examined versus standards we would like to adopt in modern landfill mining. In this article we discuss the landfill mining carried out at an anonymous site referred to as the “demonstration site”.

Discussion

The industrialized West Midlands in the UK known as the “Black Country” has a varied history, including coal mining during the 19th Century from shallow seams that sub-cropped beneath the cover soils, metal processing and, since the early part of the 20th Century, for waste disposal. Our demonstration site is in a general area that was used for mineral extraction and disposal of wastes until the late 1960s. Materials deposited at the site included builder’s wastes, residues from local metal refining processes and household wastes from a local District Council. Tipping was carried out over three discrete areas.

Immediately prior to the redevelopment undertaken by a Government funded Development Corporation in the early 1990s, it is recorded that the wastes present at the site comprised the following:

- Late 1960s and early 1970s domestic waste, with some inert industrial waste;

- Pre-1954 (Clean Air Act) domestic waste, mostly burnt waste and ash; and

- Colliery spoil.

During the early and mid-1990s, the whole of the demonstration site was landfill mined by specialist contractors working for the Development Corporation. The site was then redeveloped for housing and commercial use with unsuitable wastes being redeposited in an engineered repository. This redevelopment included significant earth moving and excavation to expose shallow coal seams and extract available coal reserves, following which the current landform was created.

Excavation and redeposit of the wastes within the development site was required to be done in accordance with a Waste Management Licence, and in fact three licences were issued. This paper is only concerned with the areas of land covered by two of these three licences. The land was divided into two main areas: an eastern segment of about 9ha, which is planned for redevelopment and has been known historically as the ‘Development Area’, and a western segment of about 15ha, which was known as ‘The Repository Area’ and has been the subject of a number of investigation reports.

In the Development Area, the excavation was backfilled with inert material that was compacted in ‘lifts’ to create a development platform. In the landfill area, however, an engineered repository was created within the opencast void to accept a mixture of aged and more recent domestic waste, as well as potentially contaminated soils from other areas of the Black Country being redeveloped. During the redevelopment of the area, the more recent domestic waste, containing a higher proportion of biodegradable material than the aged waste was deposited directly on top of the colliery waste without any liner, cap or levelling of material. All this material was excavated, sorted and replaced within the engineered repository in the mid-1990s.

The landfill was designed and constructed as an engineered containment facility. Construction was initially carried out under a design and build (D&B) contract and very few ‘as-built’ engineering drawings are available for its construction. The Waste Management Licence (WML) for the site required the formation of a 1m thick ‘engineered mineral liner,’ with a maximum permeability of 10-9 m/sec on the base and sides of the void left after open working, together with a minimum 0.3m thick granular protection blanket above the liner. Archived, pre-construction design information makes reference to a minimum thickness of 3m of clay, sourced both from site and imported, on the base and sides of the opencast excavation, while a later design note makes reference to a 5m thickness of clay adjacent to the railway on the southern margin. .

The landfill accepted a significant amount of sorted waste soils that had been stripped and stockpiled on site, together with waste soils from various sites nearby that were also being redeveloped. Anecdotal information indicates that the amount of waste soils requiring disposal at the site significantly exceeded the original estimates, and that this was accommodated by the D&B contractor undertaking additional heavy compaction in order to create the current landform. The amount of heavy compaction that took place is considered likely to have had a detrimental effect on the integrity of the drainage pipe work at the base of the landfill. Because of the presence of a proportion of biodegradable material, the design incorporated a gas extraction system to remove and flare landfill gas generated within the repository. This system has never worked efficiently, owing to varying depths of water within the extraction wells.

The waste management licences set triggers for metal concentrations in soils that could be re-deposited on the Development Land, as well as what could be allowed to go into the engineered repository. The selected triggers were based on ICRCL total metal concentrations, which were designed for redevelopment purposes at that time; they were not based on “risk”. There were significant quantities of wastes that were not biodegradable and that were disposed of as a result of metals contamination. Much of the material was highly cohesive and by current standards may have been re-useable as non-waste. There was no segregation of the different categories of wastes that went into the repository. As a result, wastes were mixed thereby removing any possibility of re-use of material at a later date.

The original site investigations carried out to determine the types and amounts of waste likely to be encountered during the mining operations significantly underestimated waste quantities to go back into the repository. To some degree, this was unavoidable due to the nature of the site conditions and history, but the mode of engineering used a lot of excavated clays that could have been reused for development or capping/cover systems.

Phasing and mode of deposit were based on filling the whole of the engineered basal footprint rather than sub-phasing and segregation of waste types. Biodegradable materials were disposed of alongside non- biodegradable (metal washings) soils and more cohesive colliery spoils. Co-disposal and underestimation of all the waste quantities led to a strongly cohesive waste mixture that had a very low permeability. Biodegradable content was diluted with non- biodegradable, cohesive waste, which lowered gas generation rates and made subsequent gas extraction difficult. Costs of infrastructure for gas collection were also high as the whole of the site needed gas well coverage, based on the distribution of biodegradable waste redeposit.

Lessons Learned

The reclamation of the demonstration site is a very early example of landfill mining in the UK. When the site reclamation is reviewed there are many lessons to be learned for future landfill mining projects. The circumstances are as follows:

- Naturally low permeability materials were excavated and reused, but did not form the primary liner system—with proper sampling and characterisation, this could have been used as lining material.

- New clay was imported to the site for use as an engineered liner. This not only added large costs to the project but also took up valuable void space. The anecdotal evidence of between 3 and 5 metres of clay being used as basal and sideliners illustrates the amount of import required. Similarly, on a site with an average footprint size of nearly 12 hectares, this represents a large reduction in void space.

- Biodegradable wastes were disposed of with soils and other cohesive wastes without separation and/or treatment such as segregation. This reduced the amount of soil making media that could have been used for capping and cover materials.

- The opportunity to separate and place different wastes within different cells with intercellular bunds was not taken. Had it been, recovery of segregated wastes at a later date, in particular metal washings, would have been possible, thereby releasing further land for development.

- Costs of imported cover soils were high and could have been reduced if site won soils had been blended with soil making material such as compost and some imported soil. Valuable void space was again used when it could have been avoided.

- Ongoing costs of monitoring boreholes for gas and groundwater quality remain high.

- Co-disposal of biodegradable wastes with highly cohesive and metal washing waste in the same area have:

- Increased moisture content in the waste to a degree where gas generation and collection are difficult.

- Diluted biodegradable waste content thereby making gas collection expensive due the need for a much larger collection infrastructure.

- In addition, there was no segregation of glass, plastics and metals such as aluminium and Iron. This would have a value associated with it.

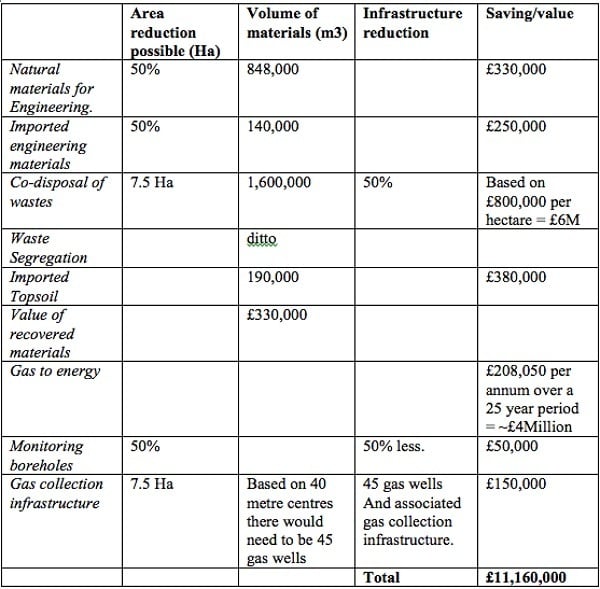

Figure 1 shows the unrealized value of landfill mining at the demonstration site.

Estimation of Gas Production Rates

In the 1990s, the use of models to estimate gas production rates was something for the future. If these techniques had been available, it may have altered the way the demonstration site was designed, engineered and the way the site was developed. The waste repository has now been modelled using Gassim-Lite to demonstrate what the gas production profile may be at the site, This model is similar to the LandGem model used in some countries and works on Monte Carlo probabilistic statistics. The site has been modelled with different moisture contents to assess the possible gas production profiles. Waste input compositions have assumed low levels of biodegradable content due to the age of the waste and to give a more realistic assessment.

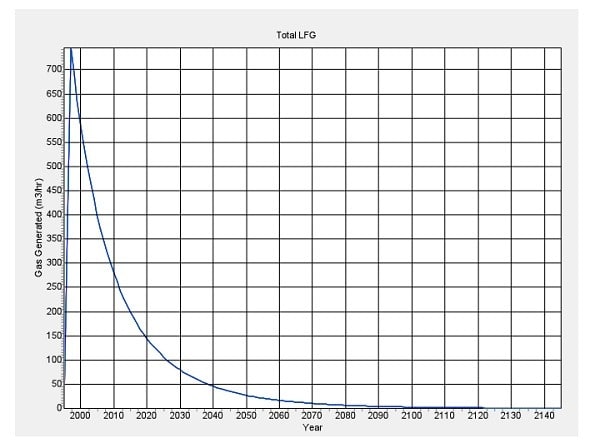

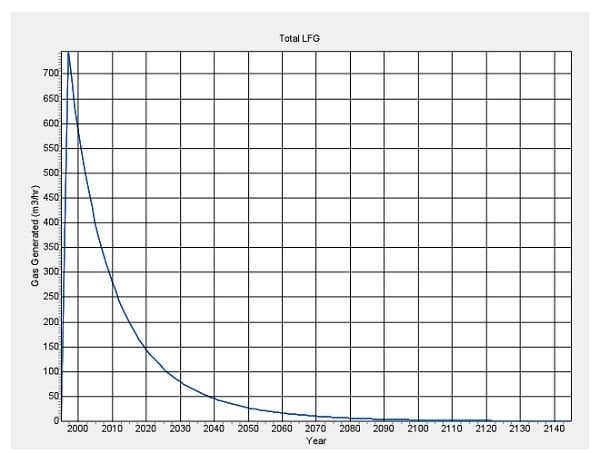

The appropriate model would have average moisture content based on average rainfall and modern methods of engineering. Gas production at the site would appear to easily to generate 250KW/hr over a 25 year period even when accounting for down time, over a 25 year period this would have generated an income of about £4Million (about $6.1 million). It can be seen by comparing Figure 2 (Gassim Lite – gas generation curve – Moisture content “Average”) with Figure 3 (Gassim Lite – gas generation curve – Moisture content “Average” – Half the area of the site) that changing the area of the site does not alter the gas production curve. This means that costs of gas collection infrastructure are double on the larger area with the same theoretical gas yield.

The theoretical modelling assumes that gas will be generated and be collected. In this case the physical conditions should be taken into account so as to reflect the reality of trying to extract gas through highly cohesive material. This would inform the decision to avoid co-disposal of biodegradable wastes with cohesive materials.

Conclusions

The demonstration repository was a convenient means of disposing of waste materials that were considered to have little, if any value at the time of development. The coarse separation of biodegradable waste, industrial wastes and soils for deposit in a permanent repository enabled the quick reuse of a large area of land. The remediated land was used for housing and commercial purposes. In the 1990s this approach of simple “sift and sort” and reduction of sterile land was used on other sites in the Black Country and to a degree the approach was effective. None of those projects considered the impact of re-depositing co-mingled wastes and did not consider the impact on gas management, leachate management and costs of non-separation of wastes with a view to immediate reuse of raw materials such as soils.

In the demonstration site case there were not only serious financial benefits to be made from separation and reuse of cohesive/non cohesive soils, but also future possibilities for re-use of industrial wastes. Separation of wastes into separate cells would have required planning, but would have allowed easy access to individual waste types. A hierarchy of possible re-use would have been needed to plan where and how wastes were separated, but this would have been possible and is something that needs to be considered for future landfill mining projects.

Co-disposal of wastes at the demonstration site led to problems with leachate and gas management control, with biodegradable waste being dispersed across a wide area and water levels within the site becoming problematic with respect to gas collection and leachate outbreaks. Re-use of soils, separation of industrial wastes and isolation of biodegradable wastes would have concentrated the area requiring gas management control, which in turn would have made gas collection easier and much cheaper. Concentrating the biodegradable wastes would have also meant that collected gas could have been harnessed into energy by using a gas engine, with considerable financial benefits. The Gassim Lite gas production curves in Figure 2 and Figure 3 demonstrate that changing the site area does not affect the gas generation profile, but it also generates tangible gas to energy potential. The use of a gas generation model prior to landfill mining would have identified the possibility of gas to energy and also informed the way cells were built and how wastes could be separated to reduce infrastructure costs and how best to realise the energy potential. Better planning and use of more modern landfill mining approaches could have led to an increase in value of the site to the order of £11million (about $17 million).

Keiron Finney is a Chartered Waste Manager and a Chartered Chemist with nearly 33 years’ experience of analysis and waste management. He now works as an environmental consultant and is Director at Exea Associates Limited (Staffordshire, UK). He can be contacted via their Web site at www.exeaassociateslimited.co.uk.

Clive Roberts, Ph.D., is a Senior Lecturer in Waste Management at University of Wolverhampton. Clive can be reached via e-mail at [email protected].

Martin Dye is a Landfill/Contaminated Land Specialist having worked at Wolverhampton City Council and has over 25 years in these areas of specialism. Martin can be reached via e-mail at [email protected].