Considerations for selecting the right telescopic crane for your business.

By Adam Oppermann

Mechanic trucks are among the most productive vehicles in a fleet. With tremendous versatility, they are an asset that can service equipment that needs onsite repair at a moment’s notice. Operators can maximize a mechanic truck’s impact by equipping it with a telescopic service crane. A telescopic service crane adds value by acting as a hoist when doing repairs, expanding the type of work that can be performed.

From building your mechanic truck, to selecting a crane, to putting it all to work for your operation, the following tips can help ensure you are maximizing the benefits for your business.

Starting from the Top: Selecting the Right Service Crane for Your Needs

Service crane selection is a critical factor in getting the best mechanic truck with a crane package that will meet your needs. You do not want a crane that is too small for the job, because it might not be able to handle the work. Going too big is also a problem, as over-investing in equipment is a drag on your bottom line. Acknowledging the most common uses for your crane plays an essential role in selection. To achieve that, all you need to do is ask yourself four questions.

#1: What Are You Lifting?

Understanding the demands of what you will be lifting can help determine if a telescopic crane is right for your business. If you have nothing to lift or only need to move parts or equipment in and out of the load bed of the truck, then maybe a liftgate is all you need. If you are lifting large parts, or pieces of equipment that require a longer reach, a telescopic crane could be the right solution. Knowing what you are lifting helps to determine how much reach you need for your crane.

#2: How Much Weight Do You Need to Be Able to Lift?

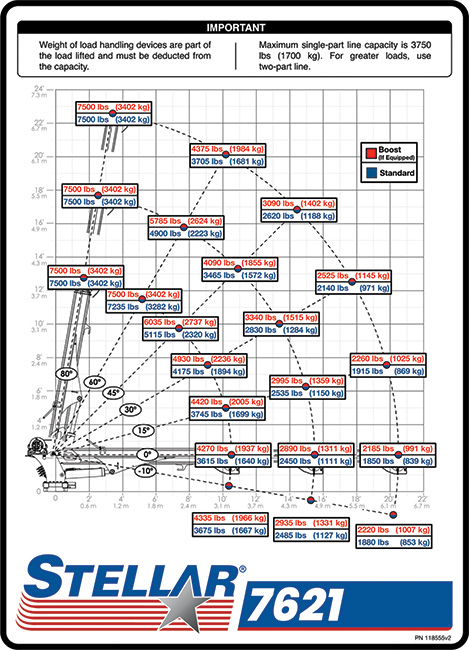

Once you have determined that a crane is right for you, you will need to determine the lifting capacity. A crane’s load capacity varies by the length of the reach and its angle, so having an idea of the likely weight you will need to lift and at what distance is essential for crane selection. To help assist you, most cranes are equipped with a capacity chart right on the crane and are also found in most manuals. This shows the operator what a specific crane can lift, at what angle, with what boom height and what horizontal distance.

#3: How Often Will You Be Lifting?

To define the duty cycle of the crane, you will want an idea of how often you will be using it. If you are going to be lifting heavy

components on a regular basis, then a hydraulic crane may be the right choice. These cranes use the chassis along with a power take off (PTO) and pump along with a hydraulic reservoir to run a hydraulic system to operate your crane. These are often paired with other hydraulically driven equipment like an air compressor.

On the other hand, if your budget is limited, your lifting needs are relatively light, or your duty cycle is intermittent, an electric crane might be right for your fleet. In general, electric cranes can offer a lower cost solution for lighter-load jobs.

#4: What Will Your Chassis Look Like?

Once you know the desired lifting capacity of your crane, this determines the matching mechanic truck body needed to handle the forces of the crane. Each mechanic truck body has a chassis specification that will aid you in picking a suitably sized chassis. Additionally, if you have a specific chassis that you want to use, you can work backwards to determine which mechanic truck body and crane sizes will work with it. The weight of the crane and body and the lifting capacity of the crane are constrained by your chassis’ gross vehicle weight rating (GVWR).

Maximizing Productivity with the Use of a Remote-Control System

Introducing a crane to your fleet can offer new levels of productivity. To maximize those capabilities, incorporate a remote-control system for your crane operation. No matter the working conditions at your jobsite, a remote control can help accomplish jobs quickly and efficiently.

At a basic level, remote control operation of a crane allows you to control and move the load wirelessly using radio waves. The

portable transmitter creates signals that are sent to a receiver permanently attached to the crane. These signals are decoded and control the hydraulic valves on the crane, causing it to move. Some remotes allow you to perform multiple crane functions at once and are proportional, giving you more precision control.

Some remote-control systems can also provide you with an expansive amount of real-time feedback. Information such as load capacity, weight currently on the crane, remaining weight that the crane can lift, and how far out the crane can be extended with the current load is just the beginning of what can be included on your remote. Some remotes even offer control over other pieces of equipment, such as lights, powering on or off your truck’s engine, speed control, air compressors, and more. One patent-pending system even estimates the distance of the load and can calculate capacity from the operator’s location when holding the remote, before ever moving the crane.1 This will help you avoid unnecessary teardowns and re-setups, saving you time throughout the day.

Real-time feedback can also allow you to make informed decisions in the moment to help keep the lift moving along. For example, if you can see how much more the crane can lift and how far out it can move with that weight, you can better adjust during the lift as needed.

Aside from ensuring that you and your team are working productively, real-time feedback can also be used to ensure the crane is doing exactly what it is supposed to be doing. Different remotes on the market offer feedback, such as warnings, when the crane is approaching maximum capacity and when it is overloaded. Some can also share any errors if the crane itself has issues. This cuts down on the time to diagnose problems and gets your crane back up and running faster.

Maximizing Payload, Maximizing Productivity

Selecting the right crane for your needs and understanding how a remote-control system can help is essential to taking your productivity to new heights. Another aspect to consider is the weight of your crane. The lighter the crane, the more payload that is available for the operator. Most telescopic cranes are made of steel, but some smaller cranes are available in aluminum to help maximize weight savings. If your typical lifting capacity allows for it, selecting an aluminum crane might be the right choice.

When it comes to making the most of your equipment, building a fleet with the right tools is essential. A mechanic truck equipped with a telescopic service crane is a versatile tool that can benefit your business. Asking yourself some simple questions can help you define and better understand the right telescopic crane for your specific needs. Add a service crane to your mechanic truck and take your productivity to new levels. | WA

Adam Oppermann is a Product Manager for Stellar, a 100 percent employee-owned and operated manufacturer of high-quality work trucks and trailers, in addition to service truck and van accessories. Through the innovative, growing product line and an expanding distribution network, the company has gained an international presence and become the No. 1 productivity choice in many markets. For more information, call (800) 321-3741 or visit www.stellarindustries.com.