Zero Waste Case Study

According to the EPA, packaging accounts for 23 percent of the material reaching landfills each year. While Diamond’s packaging and product designers work to make packaging more recyclable upstream, a partnership with Covanta offers a solution to increase recycling and eliminate landfilling from the manufacturing process.

By Shelby Mattia

Founded in 1911, Diamond Packaging of Rochester, NY, is an innovative packaging company dedicated to sustainability. With a specialty in developing paperboard and plastic folding cartons, the company serves global businesses in a variety of sectors including personal care, health care, pharmaceutical, nutraceutical, and the food and confectionery industries. Diamond Packaging’s clients include Bausch & Lomb, Beiersdorf, Coty, Elizabeth Arden, Estée Lauder, Godiva Chocolatier, L’Oreal, Otter Products, Procter & Gamble and Shiseido.

The Green Team

In 2007, Diamond Packaging’s “Green Team,” a select group of environmentally-conscious company personnel, launched the Greenbox Sustainability Initiative. The initiative seeks to balance profitable business practices against environmental considerations by promoting sustainability in all aspects of packaging design and production. Also in 2007, the company committed to purchasing clean, renewable wind energy for 100 percent of its electrical energy requirements.

The Greenbox Sustainability Initiative affected every layer of Diamond Packaging’s business, requiring a total review of its design and packaging methods, as well as the evaluation of all materials and suppliers, in order to make the best recommendation for each product. It also enhanced Diamond Packaging’s chain of custody capabilities and the company has since obtained Forest Stewardship Council® (FSC) Chain of Custody certification from the Rainforest Alliance.

At the Forefront

However, not all waste is created equal. In order to reach zero waste-to-landfill, companies may need a variety of waste management options and partners to handle different manufacturing waste streams. In the past, Diamond Packaging processed most of its profiled or regulated waste in a different facility, which was expensive and environmentally inefficient.

For a company that already has innovative sustainable solutions in place, the main challenge for Diamond Packaging was to continue to bring fresh meaning to that definition and remain at the forefront of green business operation. After more than a century of sustainable business practices—in an industry where waste can mount quickly—making continued inroads often comes down to the incremental steps a company chooses to take. Diamond Packaging chose the road less traveled, becoming the first American-owned folding carton manufacturer to achieve zero manufacturing waste-to-landfill status.

Bringing in a Partner

Despite the significant progress made over the next few years, the effort was far from finished. A strict analysis of the company’s operational methods in 2011 provided a critical opportunity for the implementation of impactful sustainability practices beyond the design phase. Specifically, the company foresaw greatly enhanced recycling, energy efficiency and process improvements, and the opportunity to recover energy from end-of-life materials. In order to bolster its capabilities and achieve their goal, Diamond Packaging’s Green Team partnered with Covanta (Morristown, NJ) to find environmentally-superior and economically-beneficial solutions for its regulated non-hazardous waste and eliminate the need for landfilling. Covanta’s zero waste-to-landfill solution was introduced through Diamond Packaging’s hazardous waste management partners as a sustainable alternative for non-hazardous regulated waste disposal.

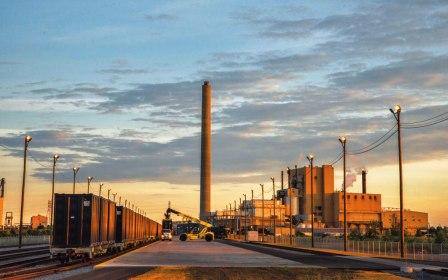

Covanta has a nationwide network of solid and liquid material processing, recycling and energy-from-waste facilities that provide better uses for waste materials and allows companies like Diamond Packaging to achieve zero-waste-to-landfill status. Covanta and its subsidiary, Covanta Environmental Solutions, provide customers with reliable, alternative solutions to landfilling waste by helping them move up the waste hierarchy, from disposal to prevention, through the use of the four Rs: Reduce, Reuse, Recycle and Recover.

Although there are costs associated with many facets of green manufacturing, many companies justify them in terms of their contribution to the greater good and because customers are increasingly demanding more sustainable products and services. For its part, the Green Team at Diamond Packaging sees a measurable financial benefit accompanying its environmentally-sustainable manufacturing practices as a direct result of its relationship with Covanta.

Diamond Packaging’s already strong recycling program was enhanced to divert and recycle 98 percent of company waste, including paperboard, office paper, plastics, metals and spent bulbs, printer toner and e-waste. Any remaining waste was sent for energy recovery at Covanta’s energy-from-waste facility in Niagara Falls, NY.

Continuing to Grow

By July 2014, Diamond Packaging leveraged the benefits of its partnership with Covanta even further, expanding it to include sending its municipal solid waste for clean energy conversion at Covanta’s energy-from-waste facility. By September of that year, Diamond officially announced it had succeeded in achieving its goal of zero manufacturing waste-to-landfill.

Achieving zero manufacturing waste-to-landfill status—the pinnacle of sustainable business practice—was just the beginning. Diamond Packaging continued to forge new partnerships, eventually finding a way to “close the loop” on its manufacturing reuse. Today, the company is the start and end point for its own waste stream. With the help of Covanta, as well as additional partners, the waste stream that leaves the Diamond Packaging facility eventually returns to it in the form of raw materials or the basic materials from which a product is made.

Diamond Packaging’s sustainability efforts have evolved steadily in recent years. The company’s ability to “right size” projects by carefully determining the correct amount of material needed per project has become second nature. Simultaneously, the company has continued to recycle paperboard, while also finding better end-of-life uses for leftover metals, wood pallets, plastics and additional materials.

According to the EPA, packaging accounts for 23 percent of the material reaching landfills each year. While Diamond’s packaging and product designers work to make packaging more recyclable upstream, the partnership with Covanta offers a solution to increase recycling and eliminate landfilling from the manufacturing process. Companies in a variety of sectors are looking to go zero waste-to-landfill and Diamond Packaging proves that such a goal is an attainable, environmentally-friendly and economically-sound achievement.

Shelby Mattia is Solutions Sales Manager for Covanta Environmental Solutions. For more information or to request a service, visit www.covanta.com/Customer-Support/Request-a-Service.