When combined with air monitoring and toxicity data of individual compounds, it is now possible to proactively alert a facility of any health-related issues that may accompany nuisance odors. This provides quantitative data on health impacts so the operator can effectively respond to frivolous lawsuits and ensure the public of the safety of their operations.

Jesse Levin

Hightened public sensitivity to odors, expanding urban development that encroaches on areas previously set aside as buffers and increasing stringency of regulations have placed added pressure on operators of solid waste facilities. The old saying “I smell money” when referring to a site’s odors issues has done an about face on our industry. That saying now applies to law firms targeting our industry by encouraging class action lawsuits.

For years odor and dust control companies have relied on a facility’s knowledge of their operations to treat odors and dust. The process has been random in the design of odor and dust control systems. This includes onsite process changes to prevent odors and to treat fugitive odors before they migrate offsite and become a nuisance to those that live work around these sites.

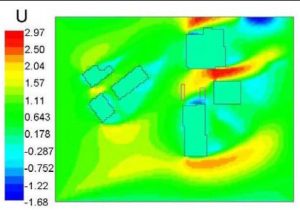

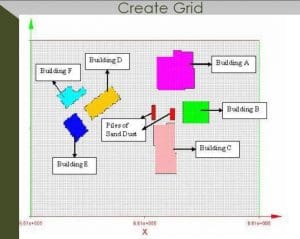

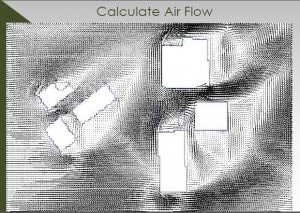

That landscape has now changed with the integration of advanced models that provide a detailed picture of the movement and dilution of dust and odors, such as computational fluid dynamics along with powerful visualization tools to display the movement of fugitive dusts and odors with unprecedented accuracy.

When combined with air monitoring and toxicity data of individual compounds, it is now possible to determine if air emissions from a site lead to potential health risks to the public. This approach proactively alerts a facility of any health-related issues that may accompany nuisance odors. This is not just good PR. It provides quantitative data on health impacts so the operator can effectively respond to frivolous lawsuits and ensure the public of the safety of their operations.

Without this information, owners and operators are put in the position of having to defend their operations to a skeptical public. To say that their facility is in compliance with applicable regulations misses the point since the public distrusts the government and the regulatory process. The issue is: “Is the operation of a facility likely to harm the public?” Remember, the public equates nuisance odors and dust with physical harm.

A Three-Step Process

Below is a three-step model to aid sites in spending money more wisely, designing proper odor and dust control systems, and maximizing the data available to them.

Step #1

Wind study + dispersion modeling together will delineate the actual pathway of odors. The purpose of a study like this would be to show without a doubt where the wind goes and where the site’s fugitive odors and dust will travel. The reason for this type of study is to validate or invalidate complaints and create a map of the site and surrounding area, showing the flow and density/dilution of wind and odors. This identifies potential complaints, confirms where an odor control system should be located as well as times of the day and weather conditions system should be operating. This study also acts as a factual document to supply regulatory agencies and community groups showing the dispersion of odors and dust into the community and the company’s treatment plan.

Step #2

The wind study + dispersion modeling results are used to evaluate the site’s existing odor and dust control systems. Making any modifications to the system—for example, controlling the duration of individual segments of the odor control system by tying in a weather station—will allow the operator to program the variables found in the before mentioned study to control the odor control system operations. The wind speed and wind direction data can be used to program the odor control system operations. The weather station will continually collect data and show when the programmed variables are met, show that the odor control system was on, show duration of run time and show when those variables are not in play justifying why the system is on and why it is off. If a site does not have a odor and dust control system, the before mentioned study will aid a company in designing the proper system for that specific site and the target areas identified in the study. This is hard data that can be used by the site to aid them in spending money the right way.

Step #3

Collect air samples at the site and at selected offsite locations. Analyze the air samples to quantify the concentration of individual toxic air pollutants. Translate the measured concentrations into public health risks—for example, in terms of cancer risk by using the latest toxicity data recommended by the EPA. This step quantifies any public health risks from exposure to air pollutants that may be generated at the site.

Optimize the Use of Your System

The overall approach outlined in this article will aid owners and operators to optimize the use of their existing odor and dust control systems, help in designing new systems and provide crucial data on the public health impacts associated with their operations.

Jesse Levin is President of NCM Odor Control (South River, NJ). Short bio? He can be reached at [email protected].