With landfill operations, internal recycling programs and a single-stream MRF that handles more than 800,000 tons of materials annually, OCRSW focuses on education messaging and working with the haulers to fix any contamination issues while implementing efficient long-term operation strategies.

Outagamie County Recycling & Solid Waste (OCRSW) has operated a landfill for more than 45 years and a recycling facility for 21 years. In 2001, Outagamie County, along with Brown County and Winnebago County, formed the Tri-County Partnership. The purpose was to share resources and costs to provide waste management services to more than 250,000 households in the three Northeast Wisconsin counties. In 2009, Outagamie County became the regional operating MRF for the three counties and has been operating the regional landfill since 2015.

The Tri-County Recycling Facility is a single-stream facility. It has the ability to process more than 100,000 tons annually. The materials that are sorted and sold include: old corrugated cardboard (OCC), old newspaper (ONP), mixed paper, PET, natural HDPE, colored HDPE, mixed plastics, aluminum, steel and cartons.

The Tri-County Regional Landfill opened in January 2015. Prior to this, OCRSW operated two landfills on their campus. The first opened in 1975 with closure and capping completed in 1988. The second, and most recent landfill, began operation in early 2000 and closed in conjunction with the opening of the regional landfill in 2015. The current regional Northeast Landfill comprises of 7,955,000 cubic yards of capacity giving it a 10.7 year lifespan. In recent years, advanced landfill compaction techniques and use of spray-on ADC have been implemented and will save airspace and extend projected site life beyond 2022. All three landfills are on the same landfill gas extraction system.

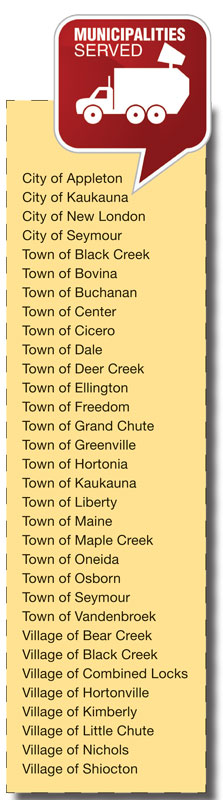

OCRSW now has a total of 32 employees that oversee the landfill operations, internal recycling programs and single-stream MRF operations that handle more than 800,000 tons of materials annually. In 1993, Outagamie County became the legally-established Responsible Unit (RU) for developing, implementing and maintaining state-mandated recycling for the entirety of Outagamie County—serving 32 municipalities—which equates to approximately 189,000 residents and 68,000 households by providing contracted recycling collection (see Municipalities Served sidebar).

OCRSW also serves communities and residents throughout Northeast Wisconsin by providing a recycling and waste drop-off site. In 2020, OCRSW opened their Resource Recovery Park. This redesigned drop-off site encourages source separation for various materials resulting in expanded recycling efforts. Using a drive through ramp design, different color dumpsters are placed in recessed ramps so at unloading level they are only three feet high. Down the ramp the dumpsters are placed in a repeating color pattern. Residents drive up to a group of colored dumpsters where they sort out scrap metal, clean wood, construction and demolition (C&D) materials, trash and single-stream recyclables (SSR). Alexandra Nett, the Recycling and Resource Recovery Administrator for Outagamie County Recycling & Solid Waste, explains, “Placing these dumpsters together makes it easy for the residents to sort their materials as the farthest they have to walk would be 30 feet. We are able to process the clean wood and sell it as mulch and animal bedding. The C&D materials are sorted through for other recoverable materials then run through a shredder and used as beneficial material in the landfill. Scrap metal and the SSR are recycled. The remaining trash dumpster is hauled to the landfill. Other materials that we collect at our site include clean asphalt shingles, e-waste, appliances, bulbs, batteries, yard waste, tires, used motor and cooking oil, furniture, stone and dirt.”

Embracing and Adjusting to Challenges

Embracing and Adjusting to Challenges

Considering recent events over the past year, Nett says the largest effect COVID has on their operation is changes to their daily procedures to ensure staff safety. For example, they have implemented safety procedures such as social distancing, mask wearing, daily temperature checks, ramped up cleaning procedures, and staggered arrival times and lunch breaks. While their workload has remained relatively the same, with only minor upticks in residential materials and less commercial materials, due to supply and demand issues resulting from COVID, they have seen changes in some of the commodities they sell. “While most of our pricing rose last year, OCC was one of the biggest affected. OCC pricing and demand rose exponentially in the second quarter, while plastics became hard to move due to trucking demands. Fortunately for us we have been able to maintain operations with only slight hiccups like this throughout the pandemic,” says Nett. “We did have to reach out to some different buyers for the PET plastics and it was on a first come first served basis. As for cardboard, we focused on sorting as much as we could from the other streams such as paper.”

Nett points out that OCRSW’s most challenging issue is contamination. While they maintain an outstanding 8 percent residual rate in the MRF as a result of education messaging and working with the haulers to fix any contamination issues, some materials still end up baled with other commodities causing contamination. “We believe that contamination is the industry’s largest issue. No matter what facility you speak with, it seems that there is always a contamination issue. Residents either not caring enough and disregarding what they put in their carts, or residents caring too much and “wish-cycling”—all cause the same issues for us. This is why education and clear and concise messaging across all three counties is something we work hard to achieve,” comments Nett. “Getting our residents and commercial customers to recycle right is a daunting task. We use a variety of methods to get our messages out. Tri-County Recycling has used pamphlets, brochures, TV commercials, radio ads and interviews, billboards, direct mailers and every form of social media (Facebook, Twitter, Instagram, Youtube, Pinterest and TikTok). In the past six months, we have focused a lot of energy into our social media, with the intent to reach more people during the pandemic. We’ve had a lot of interaction that way; however, getting our messaging out to a majority of our residents can be quite difficult.”

throughout Outagamie County. Photos courtesy of Outagamie County Recycling & Solid Waste.

Another big challenge is contamination and recycling markets. With the decline in pricing and demand resulting from China’s National Sword ruling, OCRSW felt those effects in their facility. While they were not exporting materials and did not lose any buyers as a result, they did feel the shift in demand and the drop in pricing.

OCRSW’s contracted labor force that is employed in the MRF consists of nearly 60 employees that operate on two production shifts and one maintenance shift. They are contracted through Leadpoint. When an employee is hired through Leadpoint, they are trained on a variety of tasks that are required throughout the plant and are required to meet a certain picks per minute (ppm). “We have worked with Leadpoint for nearly four years and they have increased our staffing numbers on both shifts. Their staff and training has contributed to our low residual rate as well,” says Nett.

Forming a Partnership

In 2001, Brown, Outagamie and Winnebago Counties (BOW) of Northeast Wisconsin entered into an Intergovernmental Agreement to operate the regional landfill(s) and recycling facilities in lieu of operating three smaller separate facilities. This agreement was signed to form a partnership between the BOW counties that allowed more efficient and cost-effective management of waste and recyclables through increased economy of scale and through the sharing of risks and benefits.

In 2018, the BOW partners completed an evaluation of the existing BOW agreement to validate its success and to determine the next step for future BOW operations. This review resulted in confirmation of BOW benefits—with the largest change to share in more costs including hauling and revenue—and the resulting negotiation and signing of a Restated and Amended Intergovernmental Solid Waste Agreement (Amended Agreement) in November 2020.

“The BOW partnership has saved the citizens, municipalities and businesses of the three counties more than $48 million since its inception in 2003 demonstrating that working together has benefited the municipalities, businesses and citizens of Northeast Wisconsin,” says Nett.

The Next Steps

One project that is scheduled for construction later this year includes converting the gas collection system to an RNG plant. In December 2020, OCRSW shut down their co-gen facility and have since switched to flaring through their enclosed flare. Working with Mas Energy, an RNG conversion plant will be built in line with their vacuum system. After cleanup through the plant the gas will be injected into the natural gas line.

OCRSW is also currently planning for the next landfill on the campus. Tentatively scheduled to begin accepting waste in 2023, it will be comprised of 80 acres and will have a lifespan of 15 years. In addition, they plan to focus on their C&D processing in the coming years. Currently, they are able to sort out and recycle scrap metal, clean shingles, clean wood and recyclables, with the next focus on finding a market for vinyl

siding and shredded gypsum board. The remaining C&D materials are shredded and used as beneficial cover in the landfill. Says Nett, “The implementation of our new Resource Recovery Park is the crux for making this program feasible. If we can get the drop-off customers to sort out the items we can recycle, then half of the work is already done, making our jobs easier.” | WA

For more information, contact Marissa Michalkiewicz, Recycling and Solid Waste Program Coordinator, at [email protected].