An ergonomic armrest in a refuse truck is essential to address the unique challenges faced by drivers in waste management. It promotes comfort, reduces fatigue, enhances control, and contributes to the overall safety and efficiency of the garbage truck operation.

By Martin Bertilsson

Driving a refuse truck can be a unique and challenging experience, with both positive and demanding aspects. Prioritizing ergonomic factors can contribute to the overall well-being of the machine operator and enhances the productivity while minimizing the risk of injuries and fatigue.

Refuse truck drivers often work independently, with a route to follow and tasks to complete. This can provide a sense of autonomy. Many garbage collection routes follow a routine schedule. Drivers often have set routes and familiar stops, which can create a predictable workday. In addition, the drivers may have regular interactions with the community as they pick up trash, which can lead to a sense of connection with residents. However, the physical demand requiring lifting and constant movement can be mixed in with an even more dangerous path—a monotone work environment with repetitive tasks.

Safety and Comfort

Ergonomic work environment is crucial for refuse truck operators to ensure their safety, comfort, and efficiency on the job. Following are some key aspects of ergonomics for operators:

Seat and Controls Positioning

• Adjustable seats and controls: Operators should be able to adjust the seat and controls to suit their body size and preferences.

• Comfortable seating: Seats should provide adequate support and comfort during long hours of operation.

Visibility

• Clear sightlines: Ensure unobstructed views for the operator to see the work area, colleagues, and potential hazards.

• Mirrors and cameras: Use mirrors or cameras to enhance visibility, especially in blind spots.

Vibration and Shock Absorption

• Anti-vibration features: Incorporate technologies to minimize machine-induced vibrations that can lead to operator fatigue and discomfort.

• Suspension systems: Equip the machine with effective suspension systems to absorb shocks and reduce impact on the operator.

Climate Control

• Temperature regulation: Provide climate control systems to maintain a comfortable temperature within the operator cabin, especially in extreme weather conditions.

• Ventilation: Ensure proper ventilation to prevent heat buildup and maintain air quality.

Noise Reduction

• Insulation: Implement noise-reducing materials in the cabin to protect operators from excessive noise levels, which can lead to hearing damage.

Operator Space and Layout

• Spacious cabin: Design cabins with sufficient space for operators to move comfortably.

• Intuitive layout: Arrange controls in an ergonomic layout to reduce the need for excessive reaching or stretching.

Training and Awareness

• Operator training: Provide comprehensive training on ergonomic best practices and machine operation to reduce the risk of musculoskeletal disorders.

• Awareness programs: Encourage operators to be aware of their body posture and to take breaks to prevent fatigue and discomfort.

Accessibility

• Easy entry and exit: Design machines with easy access points to minimize strain when entering or exiting the cabin.

• Handholds and grab bars: Install secure handholds and grab bars to assist operators in maintaining balance.

Adjustable Lighting

• Adjustable task lighting: Ensure proper lighting within the cabin, and if possible, provide adjustable task lighting for various work conditions.

Emergency Controls

• Clearly marked emergency controls: Ensure that emergency controls are easily accessible and clearly marked for quick response in case of unforeseen situations.

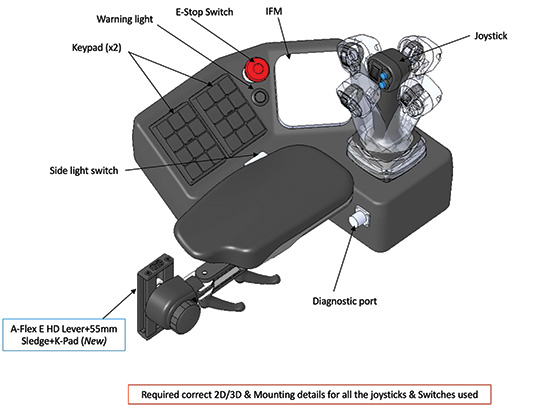

Armrest Design

We can even dig a little deeper and focus on the actual armrest with the joystick attached. The ergonomic design of an armrest in the machine is vital for the comfort, safety, and efficiency of the operator.

Operator Comfort

An ergonomic armrest provides support and comfort for the operator during extended periods of machine operation. It helps reduce fatigue and discomfort associated with prolonged sitting.

Reduced Muscle Strain

Properly designed armrests help maintain a natural and relaxed position for the operator’s arms and shoulders. This reduces muscle strain and minimizes the risk of musculoskeletal disorders, such as shoulder or neck pain.

Increased Productivity

Comfortable operators are more likely to remain focused and alert during their work. An ergonomic armrest contributes to the overall well-being of the operator, leading to increased productivity and efficiency on the job.

Precise Control

An adjustable and well-designed armrest allows the operator to maintain precise control over the machine’s functions. This is particularly important for tasks that require accuracy and attention to detail.

Customization for Individual Operators

Ergonomic armrests should be adjustable, allowing operators to customize the position to their individual preferences and body size. This ensures that each operator can find the most comfortable and efficient armrest position.

Vibration Damping

Refuse trucks may produce vibrations during operation. An air suspension seat with vibration-damping features helps absorb and reduce the impact of these vibrations, preventing discomfort and fatigue for the operator.

Minimized Operator Movement

A well-designed armrest layout can place essential controls within easy reach of the operator, minimizing the need for excessive reaching or awkward movements. This contributes to a more ergonomic and efficient work environment.

Safety Enhancement

Ergonomic armrests play a role in enhancing safety by reducing the likelihood of operator fatigue and distraction. A comfortable operator is more likely to stay focused on the task at hand, contributing to a safer working environment.

Long-Term Health Benefits

Prioritizing ergonomics in the design of armrests can lead to long-term health benefits for operators. It helps prevent chronic conditions related to poor posture and repetitive stress on muscles and joints.

Operator Satisfaction

Providing a refuse truck with an ergonomic armrest contributes to overall operator satisfaction. When operators are comfortable and content with their working environment, it can positively impact morale and job satisfaction.

Essential Component

In summary, an ergonomic armrest in a refuse truck is essential to address the unique challenges faced by drivers in waste management. It promotes comfort, reduces fatigue, enhances control, and contributes to the overall safety and efficiency of the garbage truck operation. | WA

Martin Bertilsson serves as the General Manager at Sittab Inc., where his passion lies in enhancing the ergonomic standards and work environments for refuse truck drivers. With a dedicated focus on optimizing the well-being and efficiency of these essential workers, Martin strives to implement innovative solutions that prioritize comfort, safety, and productivity. Through his leadership, Sittab Inc. continues to drive positive change within the industry, ensuring that refuse truck drivers experience the highest levels of support and satisfaction in their vital roles. For more information, call (715) 690-2992, e-mail martin.bertilsson@sittab.com or visit www.sittab.com.