After you’ve optimized your return on investment through tire inspections and maintenance.

Brian Buckham

Whether traveling down busy streets or in and out of dumps and refuse transfer stations, tires on waste haul trucks can roll across severely challenging terrain, and can be subjected to many obstacles that tires in other applications don’t typically encounter. Combine these considerations with the start-stop nature of waste haul work and the wildly varying loads that these trucks carry, and it’s imperative that fleet owners and managers keep a close eye on both tire performance and the overall condition of their tires. This includes knowing when to remove tires from service.

The only way to determine whether a tire should be pulled from service is through the performance of regular tire inspections. (Changes in tire performance noticed while driving also can indicate the existence of a condition that could necessitate tire removal.) It doesn’t take a lot of time to inspect all of the tires on a standard waste haul truck. Fleet and maintenance managers invariably find that this effort yields valuable, real-world information that enables them to make better decisions about their tire assets.

Tell-Tale Signs

So how does a fleet or maintenance manager know when a tire should be removed from service? Below are some tell-tale signs.

Visibility of Steel

If the tread is worn down so severely that the tire’s steel belts are beginning to show, it’s time to pull the tire. And if the tire sidewall has been damaged to the extent that steel cord is showing, the tire needs to be removed for repair or replacement. Keep in mind that tires in this situation aren’t always “lost.” Some can be retreaded—it all depends on the integrity of the casing. An authorized commercial tire dealer can help determine whether the tire is a viable candidate for retreading or if it should be permanently retired from service.

The Tire Has Reached a Certain Tread Depth Level at Any Point on the Tire

Every truck tire has a tread depth-determined “pull point.” According to tire industry recommendations, a drive axle tire used in waste haul applications should be pulled from service when any portion of the tread drops to 2/32-inch. Steer tires should be pulled when any portion of the tread drops to the 4/32-inch mark. Some fleets elect to pull their tires even earlier. A tire should never be allowed to operate past its pull point. Tires that are forced to run past their pull points lose traction, grip and re-treadability.

The Tire’s Tread is Wearing Unevenly

In most cases, waste haul tires are not subject to the some of the unusual wear patterns that long-haul tires can develop when they are run at sub-optimal inflation levels for a long period of time. But they can wear faster than anticipated and also develop a form of tire wear called “cupping” if components like bearings and brakes aren’t in good working order. Cupping, which happens in the tire’s shoulder area, can be caused by loose or old bearings. And the frequent stopping and starting in waste haul applications can cause brakes to wear down, which in turn, causes excessive heat build-up. Over time, this can change a tire’s components and can negatively impact a tire’s wear rate. To prevent these conditions, make sure brakes and bearings are in good working order.

Tire Inflation Levels

In addition to performing regular visual inspections, fleet and maintenance managers should pay close attention to tire inflation levels. Maintaining correct inflation pressure is the single most important maintenance practice that a fleet can employ to positively impact tire wear, casing life, overall tire life, and fuel efficiency.

Both over-inflation and under-inflation can change a tire’s footprint, making it susceptible to irregular wear and loss of traction, and should be avoided. Over-inflation can create a handful of problematic issues, including a harsh ride, but under-inflation can cause a number of more serious problems that can cost you time and money. Since the air inside the tire carries the truck’s load, under-inflation causes the tire to flex more as it rolls, which can damage the tire. Incorrect inflation also hurts fuel economy since under-inflated tires force truck engines to work harder.

Tires are designed to operate at specific pressures based on the load they are required to carry. Commercial tire dealers can help fleets determine the correct pressure for the tires that their trucks are running. Fleets should check inflation pressure levels once a week—and more often, if possible.

Proper Alignment

It also pays to keep your trucks properly aligned. At first, purchasing a truck alignment might seem like an expensive proposition, but it’s an investment that can pay big dividends when it comes to achieving a longer tire life. Over time, a regular alignment program can boost tire mileage and reduce the occurrence of irregular wear, the latter of which is not as big of a problem in waste haul fleets as it is in long-haul applications, but still can be a concern.

Truck misalignment can impact fuel economy, too. If any of the wheels on a truck are not in alignment, the total drag on the vehicle increases and more pressure is put on certain tires, depending on the truck’s trajectory.

Misalignment is not a condition that corrects itself. A truck that is out of alignment requires expert care. Fleet managers who suspect that their trucks need alignments should consult with their local commercial tire dealer, who can evaluate the situation and take the most appropriate corrective action.

The maintenance practices listed require varying investments of time and money, but can benefit fleets in real, measurable ways.

Brian Buckhamis the General Manager of commercial product marketing and future innovation for The Goodyear Tire & Rubber Company’s (Akron, OH) commercial tire business unit. A 15-year commercial transportation industry veteran, Buckham is responsible for Goodyear’s long haul and mixed-service truck tire lines, including product development, marketing strategy and other functions. For more helpful load and inflation information, visit www.goodyeartrucktires.com.

Sidebar

Inflation basics: Avoid Going Over and Under

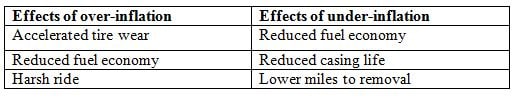

Maintaining correct inflation pressure is the single most important maintenance practice that a fleet can employ to positively impact tire wear, casing life, overall tire life, and fuel efficiency. Both over-inflation and under-inflation can have detrimental effects on a truck tire, as the chart below shows: