By harnessing the power of technology, waste management stakeholders can move towards more sustainable and efficient practices, paving the way for a cleaner and greener future.

By Tal Leemor

In recent years, waste management has emerged as a critical global challenge, necessitating innovative solutions to optimize logistics and minimize environmental impact. A key aspect of modern waste management lies in the application of advanced technologies that assist in optimizing operations. In this article, we will explore the primary technologies employed in waste management logistics and their respective use cases or stages within the overall process.

Smart Waste Bins: Transforming Waste Management at the Forefront

At the forefront of waste management logistics, smart waste bins have revolutionized the industry. Equipped with sensors and communication capabilities, these bins can monitor fill levels in real-time. This data enables waste collection companies to optimize routes and efficiently schedule pickups. Moreover, this technology aids in preventing overflow and littering, promoting cleaner urban environments.

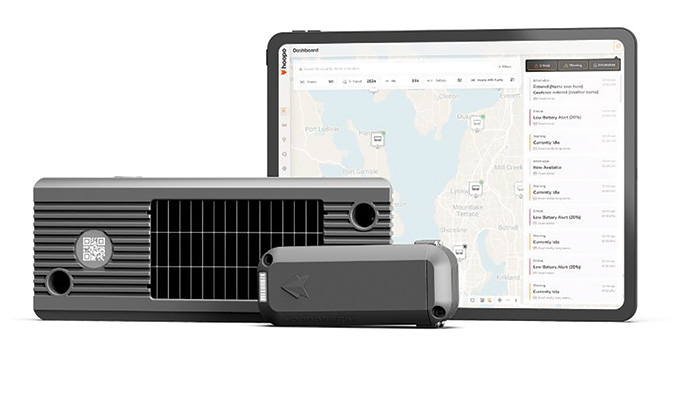

hoopoSense tracking device on 14 yard waste container

Route Optimization Software: Paving the Way for Efficiency and Cost-Effectiveness

Route optimization software serves as a vital component of waste hauling. By using advanced algorithms, this technology determines the most efficient collection and disposal routes based on real-time data, such as traffic conditions, waste bin fill levels, and even lines and landfills. The result? Reduced fuel consumption, lower carbon emissions, and increased cost-effectiveness for waste management companies.

Asset Tracking: Ensuring Precision, Progress, and Preventing Inefficiencies

Fleet and asset tracking plays a crucial role in waste management. Telematics provide precise location data for waste collection vehicles and roll-offs. These technologies allow managers to monitor equipment movements, track progress, and ensure waste disposal occurs at the right time and location. Additionally, they help identify potential inefficiencies and equipment maintenance requirements while preventing misplacement or theft of dumpsters. Using tracking devices can also increase use rates, play a pivotal role in optimizing driver tasks, and save significant time spent on yard checks or resource allocation.

RFID and Barcode Technology: Streamlining Identification and Management

Using Radio-Frequency Identification (RFID) and barcode technology, waste bins can be equipped with tags for accurate identification and tracking by the pickup trucks throughout the collection process. This technology also facilitates seamless billing and waste composition analysis, enabling better waste management strategies.

Images courtesy of Hoopo.

Predictive Analytics: Proactively Responding to Waste Generation Patterns

Predictive analytics leverage historical and real-time data to accurately forecast future waste generation patterns. By analyzing trends and seasonal variations collected from the fleet tracking system, waste management companies can optimize resource allocation, pre-plan collection schedules, and proactively respond to potential challenges, such as increased waste production during holidays or events.

Waste-to-Energy Technologies: Promoting Sustainability and Energy Generation

In the pursuit of sustainable waste management, waste-to-energy technologies have gained prominence. These processes convert non-recyclable waste into energy, reducing landfill volumes and generating renewable power. Waste-to-energy technologies complement waste hauling logistics by diverting certain waste streams away from traditional disposal methods.

Paving the Way

The adoption of advanced technologies in the waste hauling industry brings forth numerous benefits. Notable advantages include increased efficiency, improved sustainability, and enhanced safety. Technology optimizes equipment use, improves waste collection, transportation, sorting, and recycling efficiency, leading to reduced costs, improved environmental performance, and a better customer experience. Furthermore, it aids in reducing the amount of waste sent to landfills, thus protecting the environment, and conserving natural resources. Additionally, technology plays a significant role in preventing overflowing containers, detecting leaks or fires, and tracking the location of waste collection vehicles, resulting in enhanced safety.

Effectively managing waste is a multifaceted challenge that necessitates a combination of modern technologies and innovative strategies. Smart waste bins, route optimization software, fleet tracking, RFID, predictive analytics, and waste-to-energy technologies represent just a few examples of the technological advancements revolutionizing waste management logistics. By harnessing the power of technology, waste management stakeholders can move towards more sustainable and efficient practices, paving the way for a cleaner and greener future. | WA

Tal Leemor is the Vice President of Global Partnerships and Marketing at Hoopo, a renowned provider of location intelligence through fleet digitization. With a deep understanding of global marketing and business development in emerging technologies, Tal brings extensive expertise to her role. She is deeply immersed in the entrepreneurial ecosystem and is well-versed in the tech startup lifecycle. With a wealth of experience in RF location technologies spanning decades, Hoopo specializes in tracking and monitoring Non-powered Ground Support Equipment (GSE). Their solutions optimize ground operations by enabling efficient resource planning, preventing bottlenecks, and minimizing mishandling of baggage. Tal and her team at Hoopo are actively collaborating with airports and ground handlers worldwide, working towards their vision of digitizing ground operations on a global scale. She can be reached at [email protected].