Haulers save time, money and improve customer satisfaction with monitoring solutions.

By Kirk Warren

Many haulers cannot report how full their roll-off containers are, the last time their containers were emptied or where their containers are at any given time. This results in lost time, missing or stolen containers, and additional money spent on equipment. As the waste industry continues to evolve and focus on more efficient methods of tracking and deploying roll-off containers, container monitoring provides a best-in-class solution for haulers to save time and money, while enhancing customer service.

Roll-off container manufacturers are embracing a culture of innovation with container monitoring by providing the best breed of tools to haulers nationwide. Adoption of the technology is easy for haulers when container monitoring sensors are offered on newly purchased containers from manufacturing facilities.

Through accurate, up-to-date tracking, roll-off container monitoring can ensure that haulers’ assets are being used to their highest potential. As a roll-off hauler, the more pickups you get, generally the more money you make. With the ability to track the fullness levels of their containers, haulers can increase container turns, their number of hauls and their bottom line.

verification and customer specific data.

No More Wasted Time. No More Wasted Money.

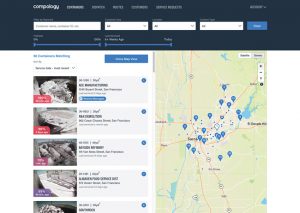

Container monitoring solves a real problem for haulers across the country. It works by using camera-based sensors that include GPS and motion tracking to allow haulers to remotely monitor location, fullness, content and service. These sensors are located inside the roll-off containers and feed up-to-date data to a Web-based software dashboard, which haulers can use to make data-driven decisions. This helps haulers save time, money and enhance customer service in a number of ways.

Automate Container Tracking

Have you ever lost your mobile phone and used a finder app to locate it? Similar to the mobile phone finder app, container monitoring is a cloud-based system that can be used on your mobile phone, computer or tablet to locate your lost or stolen container. With automated container tracking, haulers can manage their container inventory by knowing how many containers they have deployed, their precise locations, and how long they have been there right from a Web-based dashboard.

When selecting a monitoring technology, it is important to choose a system that offers much more than just “container finder” functionality. Choose a container tracking system that tracks not only precise container location, but also the length of time at that location and the exact number of containers (by size) that are deployed. Using this information, haulers can reduce the number of lost or stolen containers and increase their revenue from improved asset management and deployment.

Avoid Unnecessary Trips

Haulers often make unnecessary trips because they cannot remotely verify how full their roll-off containers are. As a result, haulers are wasting fuel and driver time to pickup low-fill containers. With container monitoring sensors, haulers can eliminate dry-runs and pickup roll-off containers when they are full, or ready to be serviced, by verifying fullness, in advance.

Anticipate Haul Schedules

Container monitoring helps haulers enhance customer satisfaction and earn more revenue with the ability to proactively reach out to customers to schedule roll-off hauls when their containers are full, rather than only when customers decide to call them in. By monitoring fullness levels remotely from their offices, haulers can provide customers with the option of more timely removal, schedule hauls more effectively and increase turns per container to drive more revenue. By scheduling pickups when needed, rather than on a set schedule, haulers can save time and money. Through container monitoring, haulers can improve efficiency by minimizing same-day hauls and route changes while improving their ability to level-load.

Prevent Theft

Materials inside the roll-off containers are valuable, especially for scrap haulers. Image-based container monitoring provides access to daily and historic images of the contents of a container. Haulers can track container fullness, monitor the materials inside a container and know the exact location of their containers at all times helping to prevent theft and revenue loss.

Get Started

Before purchasing your next roll-off container, select a manufacturer that provides image-based container monitoring solutions that are pre-built into the container. Container monitoring brings revolutionary technology to the waste industry. With this solution, haulers are operating their businesses more effectively by relying on technology, rather than manual tracking methods, to understand when and where service is needed. Implementing container monitoring improves container management, reduces unnecessary trips, allows for efficient haul scheduling and helps prevent theft. More efficient operations and improved asset management help haulers reduce the number of lost or stolen containers and equipment purchases while also improving customer service offerings and generating more revenue. By taking advantage of this cutting-edge technology, haulers can save time, money and enhance customer satisfaction.

Kirk Warren is the director of product management for the steel division of Wastequip (Charlotte, NC). He is responsible for product development, product optimization and marketing of the steel product line. Before joining Wastequip, Kirk worked 10 years on the hauling side of the waste industry as a sales manager and trainer for Republic Waste Services and Allied Waste. He can be reached at [email protected].

To understand the financial benefits of roll-off container monitoring solutions, visit www.wastequip.com/compology/compology-calculator. Haulers can enter the number of roll-off trucks they run daily and their average revenue per haul into a financial calculator. This tool demonstrates how haulers can reduce the number of days onsite per container, allowing them to redeploy the container to another customer to generate additional revenue. To get started with a container monitoring pilot program, visit www.wastequip.com/products/container-tracking-system.