Sponsored by Bandit Industries, Inc.

Since 1983, Bandit has manufactured equipment for a multitude of wood waste processing markets. The vision since the beginning is to build quality, highly productive, easy-to-maintain equipment providing years of dependable service. The commitment to quality, innovation, and dedication is instilled in every employee and is one of the main reasons why Bandit became an Employee-Owned Company (ESOP) in 2018. These core values ensure each Bandit machine will leave the factory ready to exceed your expectations.

Bandit’s horizontal grinder and slow-speed shredder models are supported by a highly trained dealer network or the Bandit factory. For those supported by a dealer, each dealer has qualified sales, parts, and service personnel that receive ongoing training from Bandit. These dealers carry a wide variety of parts and machines to meet your needs and are supported by Bandit regional sales and parts representatives. If there is no authorized dealer in your area, then the Bandit factory would handle all your parts, sales, and service needs. Bandit employs experienced and knowledgeable personnel and has multiple service trucks on the road to service our direct customers.

Bandit’s line of horizontal grinders are known as “The Beast” and are the most versatile units available on the market today. These units are the most efficient way to process wood waste and here is why:

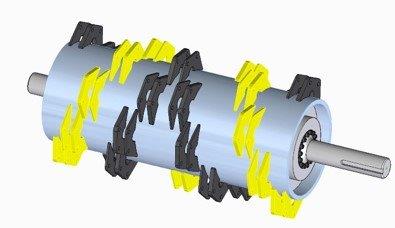

The heart of each Beast Recycler is the cuttermill that will cut material apart as opposed to the beating action of competitive grinders. This process is best described by comparing an axe to a sledgehammer, which would you prefer to use to cut down a tree?

The mill in each Beast is larger in diameter compared to most competitive grinders. These larger diameter mills will turn slower generating a tremendous amount of torque to process material using less horsepower and fuel. Since the cutting action is much smoother and more efficient, vibration is minimized resulting in reduced wear-and-tear on the machine increasing longevity.

The cuttermills in each Beast grind material in a downward motion working in conjunction with the infeed conveyor and feed wheel. This cutting process creates a more informed end product as the material is less likely to turn or roll during grinding. An anvil is mounted below the grinding chamber and acts as a primary or secondary cutting point depending on the Model. On Models 2680 on up, due to the downward cutting action the infeed conveyor acts as the primary cutting point resulting in a moving anvil for added longevity.

Each cuttermill features cutterbodies that are attached to heavy-duty support arms. The cutterbody utilizes a raker positioned ahead of the tooth regulating the cutting depth to approximately ¾”. This process correctly sizes material on the initial cut and allows the material to immediately pass through the screen and exit the grinding chamber. By grinding this way each machine relies less on the screen and gate-to-size material reducing the overall wear on the screen and gate.

A wide variety of cutting teeth are available to effectively process a diverse range of material. These teeth are either 1” or 2” wide depending on the mill size. Most models are available with a “fan” style tooth which will assist with pushing material through the screen, increasing production while reducing wear on the cutterbody. It is recommended to run at least half fan-style teeth on the models these are available on.

Screens and gates are utilized to assist with achieving a desired end product size. Available size ranges include from 5/8” to 7” hole sizes and are available in modified diamond, round and square configurations.

The screen and gate on 2680, 3680, and 4680 are changed from the inside of the grinding chamber and can easily be removed through an access door on the side of the machine. The 1680 and 2460 screens are removed from the side of the machine by unbolting and sliding the screen out from the side of the machine.

A chipper drum option is available on select models turning the grinder into a whole tree chipper with the capability to produce a dimensional chip ranging from 5/8” up to 2”. Depending on the chip size needed, a 4 or 8-knife drum will be used. For those wanting a smaller chipper in the 1/4” size range a 20-knife drum is also available.

A WDH120 infeed chain is standard and is designed to handle heavy material being loaded on it. These infeed chains carry material with less spillage compared to competitive grinders with drag-style chains. A heavy-duty feed wheel is located in front of the grinding chamber and provides additional pulling power and down pressure making it easier to re-position larger diameter pieces. The feed wheel up and forward / reverse is controlled by the radio remote control.

All models except for the 2460 track feature foldable and height adjustable discharges. Each discharge has a magnetic head pulley at the end to separate nails and other metallic debris that goes through the grinder. These discharges feature 2 or 3-speed adjustments that can be easily adjusted depending on the material being processed.

For those interested in coloring mulch, a coloring system is available as an option. This system features a coloring spray bar that is mounted above the mill making it easier to inject the colorant while spreading the colorant out evenly. This system will use minimal pounds of colorant and gallons of water per hour reducing operating costs while increasing profitability.

Proportional feed is standard on Models 2460 on up and regulates the feed system as the engine begins to lose RPM. Usually featuring a minimum of 5 feed speed settings, this system gives adequate adjustments to effectively process material of different sizes allowing each unit to create a more consistent end product.

Bandit’s offers five various units consisting of the following models:

1680 (18” x 52” mill opening / 300 – 321 horsepower engine options)

2460 (24” x 60” mill opening / 525 or 536 horsepower engine options)

2680 (35” x 60” mill opening / 540 or 755 horsepower engine options)

3680 (35” x 60” mill opening / 540 – 1,050 horsepower engine options)

4680 (45” x 60” mill opening / 875 – 1,200 horsepower engine options)

In 2018, Bandit entered into a partnership to be the North American representative for Arjes slow-speed shredders manufactured out of Leimbach, Germany. Arjes is a worldwide leading supplier and manufacturer of double-shaft slow-speed shredders. Each unit features high mobility and excels in a variety of waste processing applications. The Arjes models effectively process plastic, scrap metal, concrete, C &D, and more.

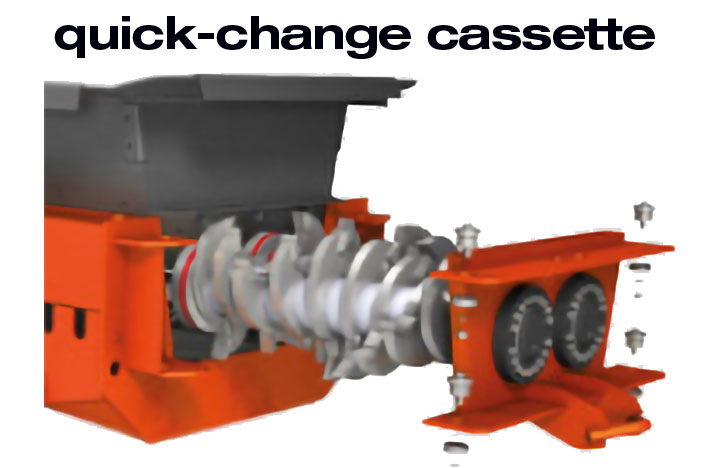

A 2-stage crushing process with special shaft geometry allows for the amazing ability for each unit to process waste at an efficient rate. Alternating shaft adjustments provide a smooth, yet powerful pulling action. Adjustable side combs further enhance the performance of each model and assists with regulating the size of the final end product.

Two different shaft options are available depending on the type of waste processed. Switching between shafts is easily conducted with the quick-change cassette system. This system reduces the amount of time required to switch shafts as the cassette easily slides out and the new cassette and shafts can easily slide back in.

Each discharge system comes equipped with an over-belt magnet to separate magnetic material from the final end product. The track units are controlled by a user-friendly radio remote control.

The Impaktor 250 is the smallest model offered and is available as a track unit with a 220-horsepower Volvo engine. A stationary electric unit can also be ordered. Customers are often impressed with the production capabilities of this unit. Weighing just under 30,000 pounds, the Impaktor 250 can easily be maneuvered and transported.

Additional models available include the Model 900 and 950 Titan class. This class is all about the heaviest chunks and most demanding applications. Available as track with a Volvo 700 horsepower diesel engine or electric stationary these units are known for their versatility and high production rates.

To learn more about Bandit equipment or to schedule a demonstration please contact your local authorized Bandit dealer or visit www.banditchippers.com.