Is your magnetic separation or vibratory equipment ready for an upgrade or replacement?

Follow these guidelines to determine whether it is better to rebuild or to buy brand new.

By Chris Ramsdell and Eric Taylor

With the pressures of a challenging commodities market and the current price tags of new equipment, more and more recycling operations are deciding to rebuild rather than to buy new. Here are some guidelines for you to consider as you determine which way to go, especially as it pertains to magnetic separation, vibratory feeders, eddy current separators, suspended electromagnets and magnetic drum separators. These basic guidelines can also be applied to all equipment used in your operation.

Track the Performance and Service Life of Your Product

Find out from the manufacturer what the predictable effective life may be for a certain type of equipment. Based upon this forecast, you can schedule the appropriate inspection to help you decide whether repair or replacement is needed.

Optimum operating efficiency and product longevity depend greatly on the individual piece of equipment and its working environment. Routine tests can determine when it is time to upgrade, replace components or purchase a brand new model.

Annual maintenance checks can be performed by qualified plant personnel or an outside party. The goal is to limit costly downtime and make sure equipment is operating at peak performance. Once an inspection is completed, the service center will be better able to determine the next course of action, whether this means replacing one component or remanufacturing the equipment to original specifications. In some cases, a total replacement is needed, but that is only after consideration is given to several scenarios to get that equipment back on line.

Consider the “Buy New” Price Compared to the Rebuild Price

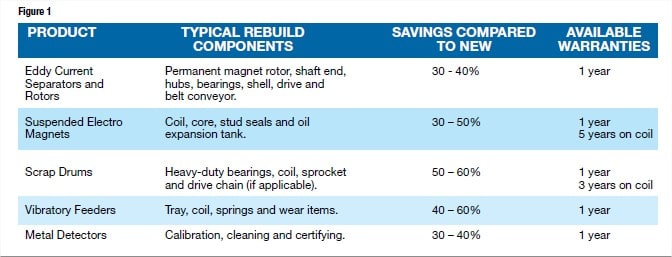

When all is said and done, the price tag for new equipment may be beyond your budgetary constraints. Figure 1 below compares the cost of rebuilding typical recycling equipment to buying new.

Research What New Features are Desirable, Including Energy Savings, New Technology and Software

As time goes on, manufacturers develop product enhancements that may be sought by your management team. Sometimes these innovations can be added during the rebuild process. Other times these improvements can only be enjoyed if a new product is purchased.

One example of a simple upgrade during rebuild is Eddy Current Separators, which are available in numerous rotor designs like: Rare Earth Arched (REA), LT2 (+1″ material) and ST2 (1/2 – 1″ material). Some rotors use ceramic tile surface shells and all use grease retainer chambers. They are typically balanced to operate at 3,000 to 3,200 RPM. You can easily choose a rotor upgrade.

In terms of suspended electromagnets (SE), several components provide an effective and efficient magnetic circuit for collecting tramp metal. These include the coil, core, stud seals, backbar and expansion oil tank.

When it comes to magnetic drum separators and scrap drums, you will find that the magnetic power of new magnetic drum separators may be incorporated into your old model. Scrap drums have certainly come a long way. Check with the service center regarding options.

With vibratory feeders, newer designed products now come equipped with energy saving components that should be explored before you rebuild or buy new. Ask for these when you place your rebuild order.

Today’s metal detectors come with software and even smart phone technology that you may wish to consider. By talking to the rebuild facility, you can investigate whether you need to go new or can upgrade your current unit.

Timing: Does Buying New or Rebuild Meet Your Timetable?

When do you need your product? Typically, it takes two to four weeks to rebuild most products. You can expedite delivery sometimes at a premium price. You will need to compare the delivery leadtime: new versus rebuild.

When you have stopped production or face safety issues that compromise your working environment, you will need to find the best answer in terms of a firm delivery date.

Evaluate Warranty and Reputation of the Company

Plant operations entail numerous pieces of equipment working together in a seamless operation to bring the finished product to market. Metal detectors, magnetic separators, vibratory feeders, screeners and conveyors all play an integral role in many operations. Recyclers use this equipment independently or in a comprehensive flow system to help increase product purity, preserve downstream equipment and improve productivity.

Since recycling equipment represents a significant capital investment, plant operators should perform routine inspections to detect any malfunctioning or underperforming equipment. This procedure helps spot trouble areas, minimizes downtime and prevents potential harm to plant personnel and downstream equipment.

There are several ways to determine which rebuild facility to trust with your upgrade project. You can ask for references from past and present customers or ask your peers who have used the facility. You can also visit the rebuild facility and see first hand the set up and how equipment is repaired and upgraded.

Warranty is also important. Be sure you understand the extent of the warranty before you commit whether you buy new or rebuild.

By checking equipment on a routine basis, repair centers can identify customers’ equipment issues and take corrective action before problems lead to machine downtime and lost productivity and profits. Repairs can effectively extend the overall life and sometimes customers can save as much as 60 percent by choosing to rebuild rather than buying new equipment.

Chris Ramsdell is the Product Manager, Recycling for Eriez (Erie, PA). He develops and implements selling strategies to expand the sales of Eriez recycling products into all Eriez markets. He can be reached at [email protected].

Eric Taylor is Supervisor, Remanufacturing Services for Eriez. He helps oversee the 5-Star Service Center, which includes a range of rebuild, repair and re-certification programs for a variety of recycling equipment. He can be reached at [email protected].

For more information, call (888) 300-ERIEZ (3743) within the U.S. and Canada, e-mail [email protected] or visit www.eriez.com.