What happens when performance properties of gloves get so good that ANSI has to add more numbers to its ratings scale?

By David Miller

We’re all familiar with the expression, “On a scale of one to 10, this is an 11!” Normally, we pass off such talk as an exaggeration. However, there is no exaggeration involved when we’re talking about the state of the art cut resistant gloves these days. The ratings systems formerly in place were devised in an environment where today’s performance levels were inconceivable.

This past year has seen both ANSI and its European counterpart, CEN, revise their standards to adjust to the new normal in cut resistant gloves. Along the way, long-standing problems that have caused conflicts between the American and European systems are a little closer to becoming solved.

As these changes make their way into the marketplace, end users who understand the new classifications will find them very useful in evaluating and comparing gloves.

What’s Changed—ANSI/ISEA 105

Let’s look at the important changes made to cut resistance testing and grading in the ANSI standard. First, there are new restrictions on the equipment choices test facilities can use to conduct the test, which is a move to improve consistency of results. But the most important change affecting the glove consumer is a redefinition of the ratings scale. The cut level scale of 1 to 5 that we all know has now been updated to go up to 9.

This was not a simple matter of adding four more numbers to the end of the scale, either. In order to appreciate this change, we must understand a little bit about the ANSI test method.

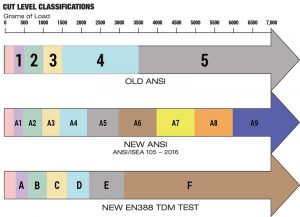

The ANSI test measures the amount of load it takes for a razor blade to slice through the test material. The test result is the weight of the load in grams. This number is used to determine the cut level rating of the glove, as illustrated in Figure 1.

Fixing Cut Levels 4 and 5

The first graph shows the former ratings system. As more gloves began to fall into the 4 and 5 categories, the weakness of the system became more evident. The range of test scores occupied by cut level 4 is as big as the previous three zones combined. Cut level 5 is even larger than that, going from 3,500 grams to infinity. It’s hard to make an informed comparison if one glove could potentially have twice the cut resistance of another glove and yet both have the same cut level.

The revised ANSI standard divides the old levels 4 and 5 into smaller zones so gloves with higher cut resistance can be compared to each other more meaningfully. To differentiate the new cut levels from the older scale, each of the new cut level designations gets the letter “A” added to the front of the number. Cut levels 1, 2 and 3 are identical to new cut levels A1, A2, and A3, but old cut level 4 could be A4, A5 or A6. Old level 5 is now A6, A7, A8, or A9.

You may have already seen cut levels advertised with an “A” in front of the number and wondered what it meant. Most glove vendors who are publishing the new cut level ratings are also publishing the old number as well until the new system becomes better known.

EN388

Now, let’s look at the new changes to EN388, the system in use by the European Union. You might be wondering why you should even care about European standards when ANSI is the standard recognized in North America. You should care because the information you get at a glance on the “hammer within a shield” EN388 badge that appears on so many gloves nowadays is extremely informative. The four-digit code on that badge tells you how that glove will perform against four different mechanical risks (abrasion, cut, tear and puncture).

The presence of this EN388 label on so many gloves in the U.S. is a mixed blessing for PPE consumers. What you gain in good, solid data on that label is tarnished by the inferiority of EN388’s cut resistance test.

In my article, “Personal Protective Equipment: Cut vs. Puncture vs. Needle Stick” (Waste Advantage Magazine, October 2016), I explained the differences in these two test methods and why there is no way to compare an ANSI cut level to an EN388 cut level, despite them both having the same 1 to 5 scale. Sometimes the same glove with an ANSI cut level of 3 will score a 5 under the EN388 test. The natural assumption that gloves with the same cut level would perform equally well protecting against cuts goes out the window when such a situation exists.

Imagine what would happen if Canadian dollars looked nearly identical to American dollars and began to be widely circulated in this country. Confusion and exploitation would run rampant. How many consumers are savvy enough to ask the question whether the “cut level 4” glove they are looking at is an ANSI “4” or an EN388 “4”?

Taking a Cue from ANSI

The 2016 revision to EN388 is a cautious move toward reconciling the shortcomings of their cut level test. Rather than dismissing the old test protocol, the revised standard attempts to limit its use to testing materials it can handle. When a glove with higher cut level properties is tested and exceeds the capabilities of the test device, the standard now prescribes the glove to be additionally tested on the same machine used in the ANSI standard. Whenever this auxiliary test is performed, the result of this extra test will appear as a fifth digit on the code of the EN388 badge, while the placeholder in the second digit of the code will become an “X” (see Figure 2).

This is very good news for consumers because it means that gloves in the higher range of cut resistance can be accurately evaluated even when ANSI cut level information is unavailable as long as they have that fifth character on their EN388 badge.

As you can see in the bottom graph of Figure 1, the EN388 TDM test scale is designated by a letter grade of A through F. The European test, though identical to the ANSI test, is rendered in newtons instead of grams, but newtons are easily converted into grams, allowing a very close comparison to the two grading systems. We can see then that a glove that scores an E in the new test is a fairly even match for a cut level A5 glove under the new ANSI scale, or a 4 under the old one. This is definitely progress.

Safety managers in companies that have mandated minimum cut levels for certain positions in their company should check with their superiors about the affect these changes may have on their rules concerning glove selection.

You will also notice that once the new standards are firmly established, there will be much less chance for someone to try to compare apples to oranges because it’s harder to confuse a cut level of A4 with an EN388 4 because the nomenclature is different enough to dispel confusion.

David Miller is the Waste Industry Manager for HUB Industrial Supply (Lake City, FL). He is a Certified Safety Professional and works with managers to effectively implement and manage PPE and MRO programs in the waste industry. He may be reached at [email protected]. HUB Industrial Supply is an Applied MSSSM company.