Personal Protective Equipment

How to protect your eyes from impact, glare, fatigue and the “dork factor”

By David Miller

When supplying eye protection for your staff, you have the opportunity to promote safety as well as long-term eye health. If you limit your offering to one or two of the least expensive models, you might be simply trading one hazard (impact protection) for a handful of others like impaired vision due to poor optics, glare, fog and added fatigue.

Impact Protection

The obvious reason for eye protection is to avoid injury from physical impacts, whether they be flying debris or a wayward tree branch. The ANSI standard for this type of PPE is Z87.1, which was last revised in 2015.

Most eyewear from fashion sources or opticians are not subjected to the ANSI testing. Both lenses and frames must pass some rigorous tests to be considered compliant, and they will indicate compliance with a “Z87+” on the temples and a discreet “+” molded or etched into the lens. The “+” on the lens may be accompanied by other marks; as long as the “+” is there, you are protected. If the glasses in question do not bear these markings, you are exposing yourself to liability and should replace them with something that does.

Prescription Lenses

Workers with prescription lenses have a few options to become compliant with ANSI Z87.1. There are several designs of safety glasses that can be worn over prescription glasses. These tend to be less fashionable than other safety glasses, as you might imagine. A more long-term option is to purchase new glasses from a provider who offers ANSI compliant prescription glasses.

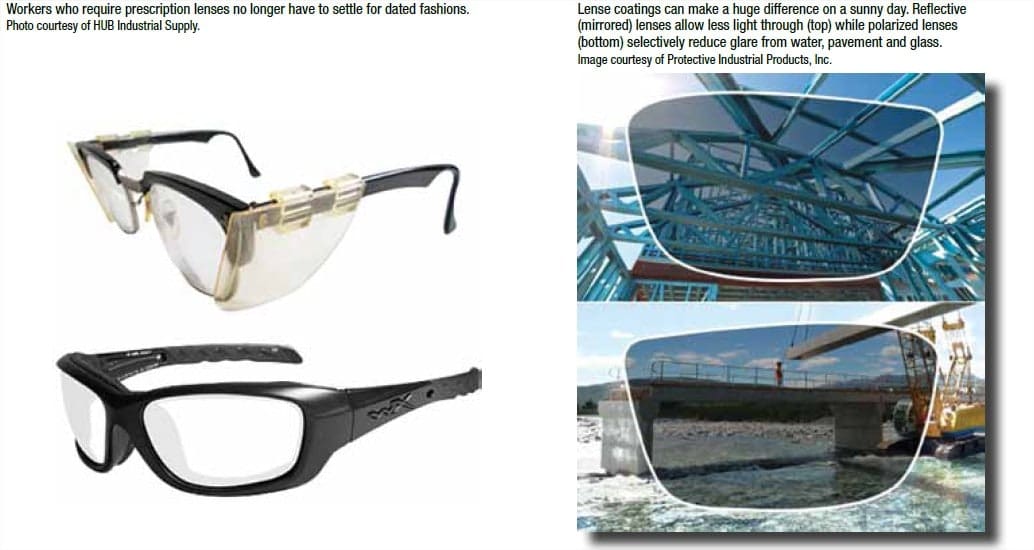

Safety glasses that contain prescription lenses face a styling challenge that non-prescription safety glasses are not constrained by: no one has quite figured out how to effectively curve a corrective lens so it can wrap around the wearer’s face and provide side protection. Some of the frames for sale today haven’t changed much from 1950s-era “industrial arts” look, complete with the quaint plastic screw-on side shields that your high-school shop teacher used to wear. Fortunately, there are a great many styles now available that have embraced the challenge of making prescription safety glasses look contemporary and stylish despite the limitation of lens shape.

Many workers who require corrective lenses are able to bypass these choices altogether simply by wearing contact lenses, which frees them to wear the same choices that you are offering to the rest of your team.

Style as a Safety Principle

In the preceding section, I made casual reference to the styling of the safety glasses, as if somehow fashion is relevant to the topic of keeping your team free from eye injuries. Style, as it turns out, is as important to eye safety as ANSI Z87. According to research conducted by a leading safety provider, 29 percent of workers do not wear proper eye protection due to its appearance.1 For every worker who claims not to care what he looks like as long as he is safe, there are many more who are focused more on the concrete—their appearance—than the abstract idea that something bad and unexpected might befall them.

Presenting safety gear that a team member believes will enhance their appearance instead of making them look dorky is a win-win for compliance as well as for the self-esteem of the team member.

Optical Considerations

Z87.1-compliant glasses start at about a dollar a pair. In addition to being impact resistant, all safety glasses with polycarbonate lenses are naturally UV-resistant. Glasses in the lower price ranges will sometimes be prone to scratching and optical distortion, limited on style and comfort, and lacking in any of the features of more expensive glasses. Some of the improvements you should consider are:

- Scratch resistant coating

- Fog resistant coating

- Tinted lenses

- Padded nosepiece and temples

- Adjustable temples to fit a variety of heads

- Foam inserts and interchangeable straps and temples

- Polarization

- Reflective coating

- Reader (diopter) zones for older workers

Anti-Scratch and Anti-Fog Coatings

Workers that move between air conditioned and ambient environments will need something to keep their lenses from fogging up every time they walk outdoors. These treatments are a film added to the surface of the polycarbonate, and some are much more durable than others.

Ergonomic Refinements

Heads come in a wide variety of shapes and sizes, so what sits comfortably on a broad face may not feel so good on a narrow face. Frames that offer rubber points of contact or telescoping temples are more likely to please a broader cross section of wearers.

Keeping Out Airborne Irritants

Hybrid glasses come with a foam pad around the inside of the frame designed to snug up against the wearer’s brow and cheeks to shield the eyes from irritating pollen and dust. Quite often, this style of glasses will also provide a strap to swap out for the temples so they can be converted into goggles. Bear in mind that a goggle strap is going to accentuate any pressure points that exist with the frame, and these frames are not as supple as traditional goggles. Unless the frames are a natural fit to the contours of the wearer’s face, the temples are usually preferred over the strap even if the foam seal around the face suffers a little. Need more isolation than that? That is what real goggles are for, man!

Tints, Polarization, and Reflective Coatings

Safety lenses nowadays come in a rainbow of tints, some of which have very limited and specialized applications. Outdoor users, such as haulers, will benefit from a tint that will minimize the intensity of sunlight. Smoke or brown tints are helpful, but on a sunny day, it really helps to deflect some of the intensity with a mirror coating, or, better still, polarized lenses.

If you are a sportsman, you may have already discovered the dramatic effect polarized lenses have on removing glare from light reflected off of water, glass and pavement. This in turn works wonders in avoiding the fatigue that results from a long afternoon spent outdoors.

The only drawback to wearing polarized lenses is they affect the appearance of phone and computer screens. If team members rely on a touchscreen to perform their duties, this could present some problems.

Anti-Reflective Coatings

While it is desirable to reflect glare away from transmitting through the glasses, glare can also reflect off the inside of the lens back into the eyes, which also causes fatigue and discomfort. Anti-reflective coatings will mitigate this problem.

Solving the Problem

The American Academy of Ophthalmology estimates that nearly 90 percent of eye injuries could have been prevented by using protective eyewear. When you outfit your team with equipment that solves that problem without introducing any new dangers, you have a policy that works for everyone.

David Miller is the Waste Industry Manager for HUB Industrial Supply. He is a Certified Safety Professional and works with managers to effectively implement and manage PPE and MRO programs in the waste industry. He may be reached at [email protected]. HUB Industrial Supply is an Applied MSSSM company.