With gradual oxidation, waste gases that were previously economically burdensome and environmentally harmful can be harnessed to create energy and electricity while simultaneously reducing detrimental emissions.

By Michael Leone

Since the 1990s, the U.S. federal government has assisted in educating businesses, governments and organizations on the benefits of biogas and has brought together producers of biogas renewable energy systems and potential customers. Furthermore, the government has established several programs that aim to provide financial assistance to businesses looking to invest in renewable technologies. For example, the USDA Rural Business-Cooperative Service program provides grants and loans to agricultural and small businesses looking to integrate renewable technologies into their operations.

The economic benefits of renewable natural gas (RNG) are not the only enticing aspect of its use, but also its ability to mitigate certain pollutants and greenhouse gas emissions. Not only does RNG reduce the emission of carbon dioxide, but it also nearly eliminates all methane emissions. With stricter emission regulations and economic incentives, there is much consideration and movement towards biogas becoming a strong alternative source of energy to conventional energy production.

The strength of biogas lies in the fact that it is a gaseous product from wastewater, landfills, animal manure or other organic material resulting from decomposition through anaerobic digestion—without the presence of oxygen—that has a great deal of energy. Typically in the past, biogas was wasted through either flaring or venting, but because of its potential use as energy, farms and landfills are increasingly using biogas to produce electricity, compressed natural gas (CNG) or liquefied natural gas (LNG) as vehicle fuel, in an effort to reduce both greenhouse gas emissions and overall facility operational costs.

The main obstacle for biogas conversion is the process of upgrading it to RNG. Because it is composed of less methane (roughly 60 percent) and contains more CO2 than conventional natural gas, biogas must go through an upgrading process in order to bring it to an acceptable level for injection into a gas grid or use as vehicle fuel. Through an upgrading process, CO2 and impurities such as siloxanes and sulfane are removed in order to upgrade biogas to biomethane (or RNG), which is roughly 90 percent methane or higher depending on state standards.

Figure 1

Water scrubbing technology schematic.

Figure 2

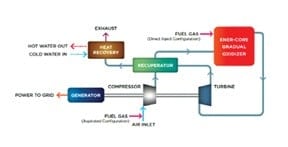

Gradual oxidation—power generation cycle.

Figure 3

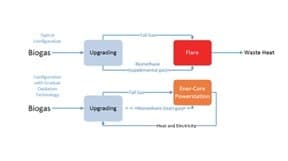

Integrating gradual oxidation in a biogas upgrading process.

Images courtesy of Ener-Core.

Upgrading Technologies

The most established upgrading technologies are water scrubbing and membrane separation, but other technologies include pressure swing adsorption. Membrane separation technology is competitive at lower flow rates, specifically 1,200 to 1,500 scfm, while water scrubbing and pressure swing adsorption are for larger operations. Water scrubbing is a physical absorption process that employs water as a solvent to dissolve CO2. Water enters through the top and raw biogas through the bottom allowing for a mass transfer through a counter-flow way. Water becomes saturated with CO2 because the solubility of CO2 is much higher than methane (CH4) in water (see Figure 1, page 22).

Membrane separation is a process that similarly relies on selecting particular compounds; as the raw biogas passes through the membrane, different compounds are removed from the membrane while CH4 molecules continue to flow and exit the membrane. Pressure swing adsorption uses high pressure in order for certain gases to be adsorbed in an adsorbent material. Because CO2 molecules are smaller than CH4 the adsorbent captures CO2 molecules, which separates it from the larger CH4 molecules. CH4 molecules are then able to be extracted from the raw biogas while leaving all other compounds within the adsorber beds.

While these technologies provide a method to extract and increase the concentration of methane in order for the raw biogas to be useable, they unfortunately are not efficient enough in methane retention, which further contributes to the emissions of greenhouse gases and cuts profits. The issue that must be addressed with upgrading technologies is its susceptibility to methane loss. Methane loss is the portion of CH4 that slips away from the raw biogas during the upgrading process. Currently, membrane separation and pressure swing adsorption are processes where methane losses can be high. Not only are profits cut because methane is lost, but also because these processes require electricity to operate and their consumption tends to increase as they reduce their methane slippage—that is, the more they process the gas, the higher the electricity usage. Methane loss not only contributes to lower profits because not all of the methane is being extracted, but it also significantly contributes to the emissions of methane into the atmosphere, which according to the EPA has a comparative impact of 20 times greater than CO2. With the loss of methane, flaring and venting technologies are considered the only solution to dealing with these waste gases because the methane content is simply too low to be used. However, a new technology has been developed called gradual oxidation that can convert these once considered waste gases into energy.

Gradual Oxidation

Gradual oxidation is an innovative power generation alternative to flaring and venting that overcomes the minimum energy density requirements; in other words its intended operation range spans from 15 Btu/scf to 2600 Btu/scf. The gradual oxidation process begins with the mixing tail gases and biomethane to start the reaction. The mixture is pressurized and introduced into the gradual oxidizer, which is heated above the auto-ignition temperature of the fuel. At this temperature, a chemical reaction releases heat energy. A prime mover can harness that energy to turn the generator and feed it back to the upgrading technology (see Figures 2 and 3). Because the thermal oxidizer is operated at pressure, its conversion to electricity is much more efficient than atmospheric oxidizers, which employ a steam or organic rankine cycle to use excess heat. The advantage of gradual oxidation is that not only does it reduce the emissions of the severe greenhouse gases like methane, but the low Btu and fuel flexibility also gives the RNG processor the ability to optimize his operations, balancing between the product methane content and energy consumption.

The question that confronts us is how we will use this excess of energy: will it be lost without profit? Or can we manage to use technological innovation to use excess gases profitably and responsibly? With gradual oxidation, waste gases that were previously economically burdensome and environmentally harmful can now be harnessed to create energy and electricity while simultaneously reducing detrimental emissions. Gradual oxidization can truly transform the way gases are used and managed. | WA

Michael Leone is a Market Development Manager at Ener-Core, Inc. (Irvine, CA). Ener-Core designs, develops and manufactures products and technologies such as gradual oxidation that aim to expand the reach of power generation to previously unusable gases. Michael can be reached at [email protected].