If you bid out the scale and software together, manufacturers who provide both products can provide pricing all in the same bid package. Bundling these two types of products together in the same RFP will save you time over the course of the bidding and purchase requisition process.

By Caleb Tidball

When issuing a Request for Proposal (RFP) for truck scales and associated weight recording software, buyers must make the decision of whether to divide up their request into discrete bids regarding hardware and software or keep their

proposal in a singular request for quote. To streamline the process, it typically makes more sense to source a truck scale and its software from a single source supplier. This article will explain the reasons why and various aspects to consider when purchasing a truck scale. When approaching the bidding process of appropriating resources, it is more practical to seek a venerable supplier that can provide all aspects of the weighing scale application that will be required for the project, including both hardware and software.

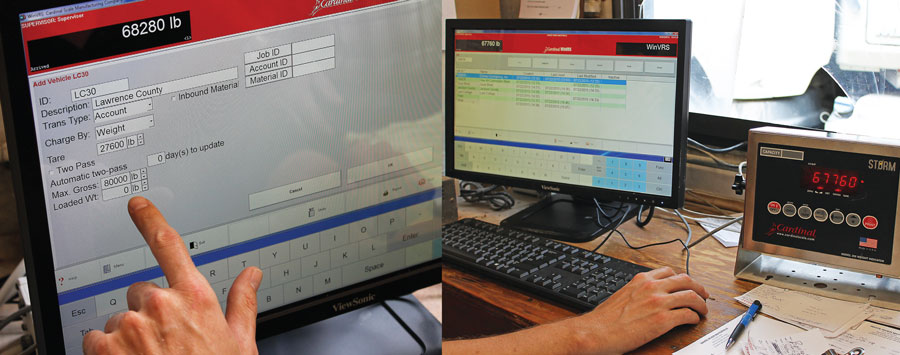

Right: Cardinal Scale’s WinVRS vehicle recording system for keeping track of truck

weights and materials flowing across your vehicle scale.

The RFP Process

The RFP process requires gathering and refining the essential requirements for developing the RFP—evaluating and selecting the most capable scale vendors, engaging with nominated scale vendors and evaluating their capabilities, making the evaluation regarding the winning vendor, and developing contractual paperwork and agreement for the winning vendor. This process requires a great amount of time and work to give the due diligence required in a large project like a full-length truck scale and related truck scale software. Duplicating this process will require even more time, work, and effort if the RFP is broken up between the truck scale software and hardware into separate bids.

Right: ardinal Scale’s WinVRS vehicle recording system and 205 weight indicator recording truck weights.

Making an Assessment

Most major truck scale manufacturers have the capability of producing not only the scale platform and the accompanying software that works in conjunction with it, but they also have the capability of providing technical support and customization for their software. Truck scale manufacturers each have different design highlights and functionality that is to be supported by the requisite software. Typically, any weight related software can be mixed and matched between truck scale manufacturers, for the most part.

Of course, several aspects of a truck scale manufacturer need to be assessed before making a decision. A truck scale manufacturer’s weighbridge and supplementary hardware should provide longevity, durability, be easily fixed should problems occur, and their hardware system should be simple and easy to use. Scale dealers and end-users should expect proactive support from manufacturers, and some truck scale manufacturers even provide remote scale monitoring that will alleviate most of the guesswork and onerous troubleshooting associated with electronic systems. Digital load cells offer many advantages for end-users, including rapid replacement times for little downtime, less issues with lightning and Cloud-based remote monitoring.

Software Needs

Regarding software, truck scale manufacturers should have a strong support presence. Access to engineering and technical support should be fairly quick and easy. There should be multiple ways to reach out to technical support: e-mail, live chat and phone. An end-user should also know the method of payment regarding subscription, one-time pricing or the price included with the purchase of the digital weight indicator. Most importantly, the software, in conjunction with the indicator, should be relatively easy to use, should be simple enough to train other employees with, and integrate easily with peripheral items like unattended weighing kiosks and printers.

Truck scale software is typically easy to configure for the user’s needs and supports truck weighing applications related to recycling, transfer stations, landfills, agriculture, aggregates and warehouses. Operators can access PC weight records and reports on period histories, material totals and customer information. The main types of truck scale software can essentially plug and play once connected with your truck scale(s). Weight will register onscreen and then the scale house operator can set up their truck IDs and materials.

A Streamlined Approach

By using the same manufacturer for both the truck scale weighbridge and the vehicle weight recording software, this further ensures a streamlined approached to get you up and weighing faster for your operation, since you have one single source for customer support interactions and plug-and-play hardware/software capabilities. If you bid out the scale and software together, manufacturers who provide both products can provide pricing all in the same bid package. Bundling these two types of products together in the same RFP will save you time over the course of the bidding and purchase requisition process. Plus, you have one contact point for all sales questions and technical support in the future. | WA

Caleb Tidball is Marketing Coordinator for Cardinal Scale Manufacturing Co. He provides marketing technical writing, trade show coordination, and marketing research analysis for Cardinal Scale’s wide range of 2,000 different scales and weighing systems. Caleb can be reached at [email protected].