In order to ensure your tipper functions properly, it is important to stay on top of daily checks, cleaning your tipper, and general maintenance. By doing so, you not only add to the life of your equipment, but you also keep your operators it safe.

By Chloe Fiedler

Landfill Tippers have become a necessity in most landfill facilities across the country. They add to the efficiency of the yard, increase the throughput of material, and allow for better use of yard space. Tippers process trailers full of debris and refuse by tipping the trailer in the air and are capable of dumping an average of 22 tons per trailer. Though these impressive pieces of equipment are common to find in most landfills, it is important to remember best practices to ensure the longevity of the equipment and safety of those operating the machinery.

Checklists

Checking your tippers daily is important to reduce future costs on maintenance and repair and extend the life of your tipper. This should include a full walk around the tipper checking for any signs of damage or debris that could inhibit its proper function. Running through a list can help to make sure no steps are missed. These lists can be done on a daily, weekly, and monthly basis.

A daily checklist may look like the following:

• All bolted connections

• All pinned connections

• All hoses and connections

• All hose fittings and adapters

• Fluids, including DEF levels

• Hydraulic pump and valves

• Engine module

• Hydraulic oil reservoir

• Hydraulic cylinders and cylinder universals

• Oil leaks

• Deck pivots

• Cylinder pivots

• Wings

• Floats

• Deck

• Frame rail

• Outriggers

• Ramps

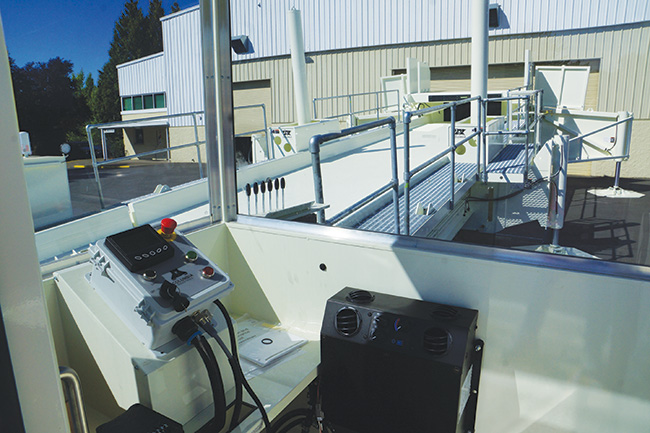

• Operator cab control box

• Electrical system and gauges

Especially important is cycling your tipper before the first tip of the day. This means starting the engine and allowing it to warm up to a medium idle for at least 15 minutes. This is important for many reasons, including checking for leaks while the system is under pressure and allowing the engine to perform a regeneration process (Regen). This is the process of burning off built up diesel particulate matter (DPM) in the diesel particulate filter. The engine needs to be up to normal operating temperature, and it takes about 15 minutes for the system to perform the Regen. It is advisable to keep the engine running at a minimum of medium idle while the Regen is occurring.

TIP: For the 15 minutes while your tipper is cycling in the morning, run through your checklist and check the rest of the tipper. Once you have completed your checklist, your tipper should have completed its cycle and will be ready for operation.

Another task that should be performed at least daily, preferably prior to the first tip of the day, is checking to ensure your tipper is level. This can be done quickly and easily with a 4′ bubble level. Measure at the backstop and the front of the tipper. Adjust using the hydraulic outrigger controls for final positioning. Your tipper representative can demonstrate the procedure if you are unsure.

A weekly checklist may look something like the following:

• Lift cylinder mounts: check for cracks, bending distortion, loose bolts or nuts, tight hose fittings, oil leakage, etc.

• Lift cylinder universals: check for cracks, bending, distortion, bearing retainer bolt tightness

• Lift cylinder box: check the support structure bolt tightness, weld cracks or bending, cylinder alignment

• Rear pivot welds: check the pin, pin washer, housing, deck arms to pivot housing, etc.

• Various welds: check manual screws, mounting bolts around leveling cylinder boxes, all floats, etc.

• Cylinder or manual screws: ensure these are in contact with float

• Pinned Connections:

o Loose pins, welds, etc.

o Rear wing bolt connections

o Rear wing brace bolt connections

o Front outrigger pinned connections

o Intermediate outrigger pinned connections

o Engine/reservoir bolt connection

o Front ramp to frame connection

• Restrainer hoops and braces: check connections

• General welds: check frame, deck, rear apron, ramps, steps, chutes, restrainers, power unit, etc.

• Hoses: check for wear or damage or leakages at fittings

• Wiring: check for loose wiring, primary and secondary

• Leveling: Ensure your tipper is level

Cleanliness

A clean tipper guarantees its proper function. It is important to keep not only the tipper, but also the surrounding areas clear of debris. A complete cleaning of the tipper at the end of each day is also important. To do a thorough cleaning, the tipper must be pulled out of its spot, the debris from around and under the tipper must be pushed to the landfill and cleared from the tipper’s spot. Make sure the spot for the tipper is as level as possible before re-positioning. Once the debris is cleaned and cleared, the tipper can be placed back for use the next day. If at any point throughout the day tipper operation is compromised by the amount of debris on or around the tipper, the process of thoroughly cleaning can be done to make sure the tipper runs efficiently.

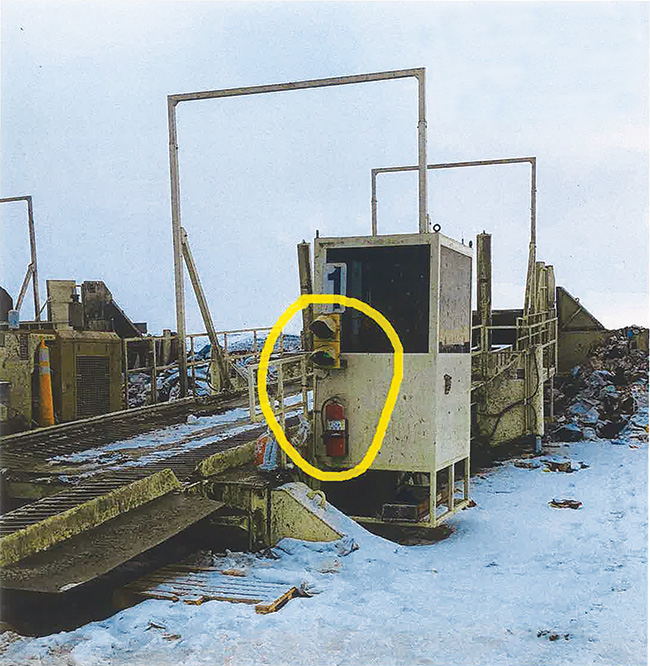

Cleaning the deck of the tipper must be completed at least two times daily or as needed. Be sure to make use of traffic lights or to raise the ramps while deck cleaning is in process to ensure the safety of those cleaning the tipper deck. The raising of the ramps or a red light on the traffic light will be sure to deter any trucks from backing up their trailer on to the tipper, resulting in injury or death of the person cleaning the tipper deck. Once the deck is cleaned, the light can turn back to green, or the ramps can be lowered for the next cycle.

Maintenance

In conjunction with keeping your tipper clean and staying on top of your checklists, you want to be sure to stay on top of maintenance. By staying current with your checklists, you should be aware of any damage or loose parts. If you come across any, you should stop use of your tipper immediately and address those issues. It may be time to schedule an inspection by your OEM (Original Equipment Manufacturer) if you are unable to address the issue yourself.

Just like with any piece of equipment, regularly scheduled maintenance inspections can help keep your tipper in good health, even extending the life of your tipper. Annual OEM inspections are a must as these individuals are specially trained to thoroughly inspect your tipper for damage, or potential weak points that need to be addressed.

It is also important to change your cylinders every two years as these frequently used parts can wear down over time. It might be best to keep some spare parts on hand to decrease downtime if there is a failure on frequently used parts such as oil filters, cylinders, air filters, etc. A certified OEM inspector would be able to recommend which parts to keep on hand.

Optional Parts

There are a variety of optional add-on parts on the market that you may want to consider purchasing for your tipper. Steel wheels have been known to add to the safety of your yard. Each year brings new fires that could pose a threat to your facility—2022 marked record highs for facility fires. Steel wheels are more durable and reliable than rubber wheels and protect your tipper from fires and flats. Rotating handrails can also add a safety feature to your tipper as they prevent accidental falls off the tipper. Dollies are another optional add-on that can help with transporting your tipper. In many cases, tippers are found in areas where mud accumulates. This can add a lot of weight, so moving it can be difficult unless you have the right equipment. Dollies act as a fifth wheel that can handle the weight of the tipper and make moving it a lot easier.

Operation

During operation, no one should be on or near the tipper except the designated operator. It is recommended that dedicated operators for the tipper should have a system in place where they are notified that the tipper is all clear for operation. This can be by means of a radio, hand signals, horn, or some other method. This is important to the safety of those in the landfill. The operator will know if someone is near the tipper and will not operate it unless given the ‘all clear’.

It has also been proven effective to have one designated traffic operator who is in charge of directing the drivers where to go within the landfill. This can reduce congestion in the landfill and add to the organization of your yard. Traffic lights on tippers are another feature some landfills have adopted. This simple but effective add-on notifies truck drivers when they are good to back their trailer onto the tipper.

Tip Top Shape

In order to ensure your tipper functions properly, it is important to stay on top of daily checks, cleaning your tipper, and general maintenance. By doing so, you not only add to the life of your equipment, but you also keep your operators safe. Keep these best practice tips in mind and you will keep your tipper in TIP top shape for many years to come. | WA

Chloe Fiedler is a Marketing Associate with Columbia Industries, a manufacturing company that has been operating for more than 50 years, creating many industry solutions for the Solid Waste, Recycling, Oil and Gas, and Aerospace industries. They make it their mission to create incredible solutions that transform industries. For more information on call (503) 531-0600 or e-mail [email protected].