Accurate gas flow measurement is essential to the gas extraction system in order to control operations properly at the landfill site.

Art Womack

A leading supplier of landfill gas extraction and recovery systems located in the Midwest region of the U.S. relies on flow meters from Fluid Components International (FCI) (San Marcos, CA) for its landfill gas flow measurements. The company has developed hundreds of landfill gas extraction system skids that are in operation worldwide, which all require accurate gas flow measurement.

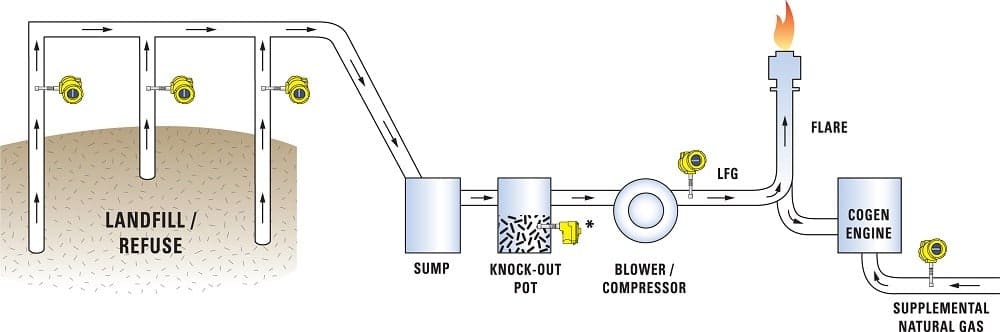

The biogas is extracted from the landfill through multiple wellhead taps and collected via a network of pipes leading to a common header. Based on the amount of biogas collected from the system, enough methane can be used as fuel gas for generators that drive turbines to produce electric power (see Figure 1). Typical landfill gas extraction systems for co-gen electric power require turbines, engines, compressors, blowers, pumps, flow meters, knock-out pots and a flare or oxidizer gas unit.

Accurate gas flow measurement is essential to the gas extraction system in order to control operations properly at the landfill site. Depending upon the amount of landfill gas produced at a given time, it can be necessary to flare off excess biogas or supplement the gas feed of the electrical generating equipment with natural gas. In addition, flow rate and totalized flow data is reported to the operators and regulatory agencies on the amount of gas being extracted, used and/or disposed of via the flare or gas oxidizer system.

The Problems

Landfill gas flow is measured at several points in the system to provide landfill operators with critical information for optimal gas production, control, safety and reporting. Landfill gas applications present several challenges in selecting the proper flow meter:

- Low flow sensitivity during start-up and seasonal changes, which produce lower flow rates

- Temperature compensation for correct readings in varying temperatures

- Calibration matched for mixed gas composition of CH4 + CO2 + trace gases

- Potentially moist and/or dirty gas with corrosive H2S content

- Potentially flammable or explosive gas installation environment (Div.1/Zone1)

- Easy, low cost installation

- Low maintenance (particularly due to the remote locations of landfills)

- Complies with Greenhouse Gas (GHG) regulations1

Landfill gas is primarily a mixture of methane (CH4), carbon dioxide (CO2), nitrogen (N2), and trace amounts of hydrogen (H2), hydrogen sulfide (H2S), oxygen (O2) and water. While a typical landfill gas mix could be 50 to 55 percent methane and 45 to 40 percent CO2, actual compositions can vary widely depending on the location, refuse types and age. An actual onsite gas analysis should be performed before specifying equipment to harvest and measure it effectively.

Also dependent upon site conditions, the landfill gas can be dirty and wet, and with sufficient H2S present can be highly corrosive to a flow meter’s wetted materials during the extraction process. Extreme conditions can dictate filtering, gas drying and/or the use of specialty metal materials, such as Hastelloy, to mitigate flow meter corrosion and ensure long service life of the components.

The production of landfill biogas can vary widely depending on the volume of refuse and seasonal changes in temperature and humidity, which means instrumentation and other equipment must be able to measure effectively with large changes in flow rates. Given this operating environment, a flow meter with a wide turndown ratio is preferred. Another consideration for flow meter selection is its capability to support different or changing gas compositions. A flow meter with on-board storage of multiple calibrations that can be user or control system selected in the field is ideal, but a flow meter manufacturer with field service technicians who can perform in-situ calibration verification and make site adjustments within the meter is an acceptable alternative.

Due to the fact that landfill gases can contain a large percentage of methane, which is highly flammable, engineered safety is a must and instrumentation has to be suitably rated and approved for the installation. Flow meters should have full instrument approvals (sensor element, electronics and the enclosure), not just the enclosure, in order to provide a higher level of safety in the installation. Applicable approvals include FM, CSA/FMC, ATEX, IECEx, and others, depending on the country.

The Solution

After identifying several potential flow meter technologies for its landfill applications, the systems manufacturer contacted FCI for further assistance. FCI specializes in thermal dispersion technology for the mass flow measurement of gases. Thermal mass flow meters provide a biogas flow measuring solution that is accurate, repeatable, easy to install and requires virtually no maintenance (see Figure 2).

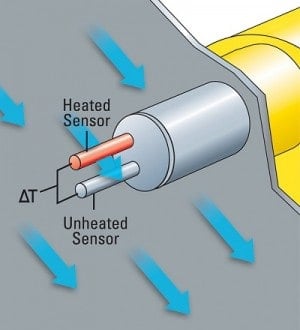

Constant power thermal dispersion mass flow measurement technology places two thermowell protected platinum RTD temperature sensors in the process stream. One RTD is heated while the other senses the actual process temperature. The temperature differential between these two sensors is measured and is directly proportional to the mass flow rate of the fluid (see Figure 3).

FCI’s constant power thermal mass flow sensing technique is unique and is frequently selected for moist gas applications because its slight heating of the sensors actually dries condensate moisture off the sensor element. This technology provides better accuracy and superior repeatability in moist, landfill gas applications.

The company recommended to the gas extraction systems manufacturer the installation of its Model ST98 Mass Flow Meter (see Figure 4), which is ideal for landfill gas measurement and features high accuracy to ±1% of reading, ±0.5% of full scale. Exceptionally consistent, this flow meter offers repeatability to ±0.5% of reading, and it does not require additional temperature or pressure compensation in order to provide accurate mass flow measurement under variable process conditions.

With its highly reliable thermal mass sensing element, this flow meter delivers precision landfill gas flow rate, totalized flow and temperature measurement. The insertion style is used in pipe diameters greater than 2 inches [50 mm], and the meter operates over a wide flow range from 0.75 to 600 SFPS (0.21 to 172 NMPS). It features a wide, 100:1 turndown ratio and operates at pressures up to 250 psig [17 bar (g)]. For applications in pipe diameters 2 inches [50 mm] or smaller, an inline meter configuration is used.

The flow meter’s transmitter features microprocessor-based electronics. The transmitter can be integrally mounted with the sensor or remotely mounted up to 1000 feet [300m] away from the flow element. Its enclosure is NEMA/CSA Type 4X (IP66) rated, and it carries global agency approvals on the full instrument for explosion-proof, Class 1, Division 1 [Zone 1] and Division 2 [Zone 2] installations.

FCI calibrates its thermal flow meter product lines in its own accredited calibration laboratory. All laboratory equipment is National Institute of Standards (NIST) traceable, as well as certified to ISO 9001:2000 and AS9000. The laboratory also meets MIL-STD-45662A and ANSI/NCSL-Z-540 requirements.

The flow calibration laboratory provides gas flow calibration capabilities ranging as low as 0.001 SCFM (0.00017 NCMH) to ranges that exceed 5000 SCFM (8500 NCMH) and can match installation conditions for applications with temperature ranges from –100° to +850°F (-73° to +454°C). Another capability that ensures the best possible calibration accuracy for landfill applications is the capability to flow actual gases and gas mix combination, such as methane, plus carbon dioxide plus nitrogen, as the calibration media.

Conclusion

When choosing a flow meter for landfill gas measurement, there are a number of key criteria to review:

- Installed accuracy with calibration matched for the site’s landfill biogas composition and conditions.

- Low-flow sensitivity with wide turndowns to accommodate variation gas flow rate.

- Multi-functional with the ability to measure both the flow rate and totalized flow

- Mass flow measurement without the need for additional temperature and pressure compensation. Direct mass flow measurement ensures accuracy in widely variable outdoor operating conditions at lowest total installed cost

- No moving parts to clog or foul in the presence of moist, dirty gases, as well as special wetted materials available to resist corrosion

- Agency approvals for use in Class 1, Division 1 (Zone 1) hazardous environments where combustible gas can be a threat to people, plant equipment and the environment

- Complies with environmental regulations, such as the US EPA’s GHG subpart HH, reporting mandate.

The flow meter chosen provides flow rate and totalized flow data from each landfill gas well to ensure continuous operation and optimal data collection. This flow meter was selected by the landfill gas extraction systems manufacturer because of its ease of installation, in-place agency approvals for hazardous areas (Div. 1/Zone 1)) and because the meter supplier is able to calibrate the meter to the system manufacturers’ requirements for mixed composition gases.

The Midwest based landfill gas extraction system manufacturer and its customers became very concerned about compliance of their installed systems as well as new systems going forward. Responding to this concern, FCI met with and worked directly with the U.S. EPA in Washington, DC, to confirm thermal dispersion flow metering technology was acceptable and further confirmed that FCI’s calibration methodology also complies with that stipulated within the mandate.

Art Womack has more than 17 years of experience in the design, production, application, sales and marketing of flow, level, pressure and temperature process instrumentation and holds a BSEE from Rose-Hulman Institute of Technology. His current position is Regional Manager for Fluid Components International LLC, a leading provider of thermal mass flow meters for the Municipal Landfill and Biogas market. Art can be reached at (760) 522-7408, via e-mail at [email protected] or visit www.fluidcomponents.com.

Note

- While not a factor originally, this is a mandatory factor in the U.S. now. The U.S.EPA enacted its GHG mandate legislation in 2009 and specific requirements for flow meters must be considered when selecting landfill gas flow meters. 40 CFR, Part 98, Subpart HH applies specifically landfill gas operations and details the full reporting and compliance requirements. For more information specifically on this topic visit web site information at www.epa.gov/climatechange/emissions/ghgrulemaking.html. www.fluidcomponents.com/Industrial/App/EPA-GHG-Mandate.asp