With the use of an Integrity Test and PPT technology with its in-situ capabilities, landfill engineering and compliance can be significantly improved.

By Reg Renaud

Current state and federal regulations require that probes be installed around the perimeter of active landfills to monitor for migration of landfill gas (LFG) through the surrounding soils. It is also required that inactive or closed landfills that indicate a potential risk to the environment or human health, must have perimeter probes installed and monitored.

There are no regulations requiring the probes be tested for integrity following installation or after many years of operation. This paper was written and presented to California Integrated Waste Management Board (CIWMB) now called CalRecycle back in 2003, since then some changes have occurred pertaining to perimeter probes and not all of them good. The changes include:

Probes under a vacuum influence used to be disqualified; now they are evaluated on a case-by-case basis if they are reported at all.

It used to be necessary to evacuate one to two volumes of air from chambers, now it is no longer necessary; how can you tell if there is water in the chambers or if the screens are plugged?

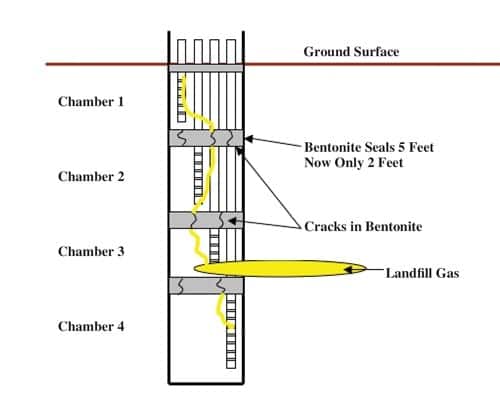

Bentonite seals between chambers were 5 feet thick, now they are 1 to 2 feet thick, which is not good.

Probe Chamber Location vs. Soil Profile

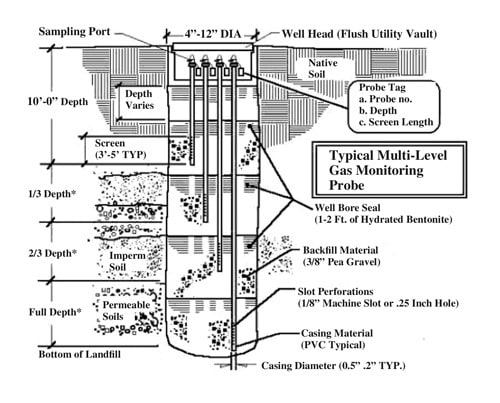

To save costs, multi-chamber probes are permitted to be installed in the same borehole instead of single chamber probes at different depths in separate boreholes. According to CalRecycle regulations, it is recommended that the chambers be installed at three or four different depths. One chamber should be 10 to 20 feet below ground surface (bgs), one at the center depth of the thickness of the refuse, another at the bottom depth of the refuse and sometimes, one 25 feet below the bottom of the refuse, if the groundwater level will allow it. It is assumed that the chambers will be installed in the more porous soil layers but discreet soil sampling is not specifically required in the regulations. The common practice is to log the cuttings from the drilling process, which is not very accurate at determining the depth of thin sand or clay layers that can control LFG migration.

Unfortunately, due to the low bid practices of landfill operators, if a consultant proposes that he will take discreet samples to confirm a porous layer, the bid will be too high and he will not be awarded the contract. The intent of perimeter monitoring would be much better satisfied if discreet sampling was required in non-uniform soil profiles. This would make the bids more even. Some thought should be given to the need of multi-chamber probes in a soil formation that has the same porosity. If the entire soil profile is highly porous, the LFG can easily move from one chamber level to the next through the surrounding soil when vacuum is applied to evacuate the probe chamber during the monitoring procedure.

Seals Between Chambers

Historically, the diagrams provided on the CIWMB’s Web site indicated that a 5-foot thick Bentonite seal should be installed between the chambers. (Figure 1, page 33, presents the new schematic of a typical multi-chamber probe.) The CalRecycle diagram shows a 1 to 2 foot seal. However, there is still no requirement to test the chambers for seal tightness following construction. Also, there is no regulation requiring that the probes be tested over time to ensure the Bentonite seals have not dried out and cracked, causing leaks.

To determine the condition of seals in multi-chamber probes an Integrity Test has been developed, which verifies if the chambers are isolated or if they are leaking and cross-connected. After performing Integrity Tests on dozens of multi-chamber probes in California only three passed the test. From this discovery, a closer look was taken at the overall installation and monitoring of multi-chamber probes and the regulations governing them.

During an Integrity Test at one of the landfills in California the reaction time for the nitrogen pressure to travel from the bottom chamber to the top chamber was so fast that the only conclusion was that the Bentonite seals had desiccated, cracked and were leaking. Had there been a longer lag time between the nitrogen pressure from the bottom chamber to the top chamber, then it would have indicated that the nitrogen was probably flowing through the soil formation or the cracks in the seals were very small. Now with only an allowable 1 to 2 foot thick seal the possibility of leaking seals is even greater.

Potential Impacts of Leaking Probe Chambers

It is now generally understood in the industry that most groundwater impacts from landfills are caused by landfill gas migration not leachate. Usually, the Regional Water Quality Control Board (RWQCB) only reviews landfill perimeter probe records after a groundwater monitoring well has indicated that the groundwater has been impacted. This is done to help in determining how and where the groundwater is being impacted. Unfortunately, by the time contamination is detected in the groundwater wells, it is likely too late for intervention. Perimeter probes are primary indicators of the effectiveness of the gas collection system in a landfill and can provide early warning of potential impacts to groundwater if properly constructed, tested and monitored. Currently, the Local Enforcement Agencies (LEA) do not have to take action until the probes indicate a methane level of 5 percent. A lot of gas can be migrating at 4 percent concentration, enough to cause impacts to groundwater quality should the LFG (which contains many chemicals of concern, COC such as polyvinyl chlorides, PVC, PCP, PCB, etc.) come in contact with the groundwater. Methane can be easily measured in the field so when it is detected you assume there are trace amounts of COCs coming along for the ride. To test for COCs requires a lab and are costly so methane is the main indicator. Also, the methane and COC levels could be much higher if the probe chamber seals are leaking. If most of the probes are indicating that LFG is migrating laterally from a landfill, whether or not the measured concentration have reached 5 percent, this can be an indication that the collection system is not adequate enough to prevent the LFG from impacting the groundwater.

Once a methane concentration greater than 5 percent is detected in a perimeter probe, it is usually necessary to investigate why the LFG collection system is not controlling LFG migration. A method of using the digital data obtained from the Piezo-Penetrometer Test (PPT) has been developed to create a 3-D Profile of the conditions inside a landfill. The PPT cone is hydraulically pushed into the landfill and the data is continuously recorded in a computer. It measures several parameters, the tip and sleeve sensors indicate the type of material it is penetrating (soil or refuse) and the pore pressure transducer measures gas/water pressure and vacuum from a nearby collector. This process is used to locate possible pathways of migrating landfill gas, which have impacted perimeter probes around a landfill.

To perform a PPT investigation it is necessary to verify the readings in the perimeter probe of concern. It has been observed that many multi-chamber probes have LFG in more than one chamber. It is important to know if LFG is migrating at two different pathways or if it is only one pathway and the LFG is leaking from one chamber to another. This helps to know whether to look for one source or two and to locate and design LFG collectors.

Flawed Monitoring Procedures

The conditions above are compounded by the monitoring procedures. The current monitoring procedures do not include methods to check the integrity of the chambers. It is assumed that once the probes are installed they will function properly, indefinitely or until obvious visual damage occurs to the top portion of the probe.

Let’s review what is happening during the process of taking readings of a four-chamber probe with leaking chambers. The technician attaches a tube from the gas analyzer to the shallowest chamber or the deepest chamber depending on the order in which the technician is taking the readings. (He should take a pressure/vacuum reading first but many do not). Historically, if it is the shallowest chamber, the technician will run the vacuum pump long enough to evacuate at least two calculated volumes of air from the chamber. (CalRecycle now says this is not necessary, they must think this will prevent crosstalk between chambers, it will not. Also how would you know if the probe is flooded with water? The new regulation states, you must check for water in the probes prior to gas sampling). This chamber may be cross-connected to the next chamber or the surface either due to leaking seals or very porous surrounding soils. If it is connected to the surface this chamber will always read low, if it is cross-connected to the next deepest chamber, the vacuum applied to the first chamber has started the evacuation of the second chamber (see Figure 2).

For this discussion, we will assume that there is substantial LFG in the subsurface at the depth of the third chamber only. When the technician starts to evacuate the second chamber and if it is cross-connected to the third chamber, LFG will start to enter the second chamber. When the technician detects the increasing level of methane he will usually keep the pump running until the methane reading stabilizes, this could be many volumes.

At this time if air is leaking from the first chamber into the second and LFG is entering from the third chamber, dilution will probably keep this chamber from reaching the 5 percent action level. During this time LFG has been pulled out of the third chamber and could lower the concentration of LFG in chamber three below the action level especially if air is entering from the fourth chamber. When the technician evacuates the third chamber the process will pull the LFG/air mixture from the second chamber and, if the third chamber is cross-connected to the fourth chamber it will be pulling air from that chamber lowering the LFG concentration in the third chamber. This chamber will probably be below action levels also. When the technician evacuates the fourth chamber the process will pull LFG from the third chamber again, lowering the concentration more in the third chamber. *It should be noted that all the above conditions and the current monitoring procedures will always cause the leaking probe to give a false low methane reading, not a false high reading.

At this time it is not known how many multi-chamber probes may have leaking chambers. Based on reviewing the monitoring records of several landfills, they seem to indicate that if LFG is detected in two or more chambers there is a good possibility that they are cross-connected. However, it can also indicate that LFG is migrating at two different elevations. Only an Integrity Test can verify which condition it is. Also, only an Integrity Test can determine if the cross-connection between the chambers is through the Bentonite seal or if the LFG is passing through the surrounding soil by the reaction time of the pressure gauge when nitrogen is applied to a chamber. This reading could be confused if the probe is installed in very granular soil. A review of the boring log of the probe may indicate that the soil type is the same granular formation down the full length of the probe and therefore a multi-chamber probe should not have been installed in the first place. Only single chamber probes can eliminate the possibility of cross-connection. But then again, if methane is indicated in only one chamber after sampling all chambers, then this indicates tight seals.

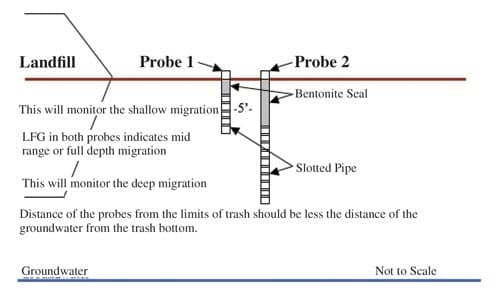

If the regulations were modified to require that future multi-chamber probes must pass an Integrity Test or be replaced, the landfill operators would probably elect to install single chamber probes. However, four separate boreholes are not necessary, only two. Currently, four chambers are required in a probe to monitor four different levels (see Figure 1). If you consider the purpose of the perimeter probes only two probes at two different elevations are required (see Figure 3, page 34). The slotted pipe of the shallow probe should be from 10 feet bgs to mid depth of trash. The second probe at least 5 feet away from the first probe would start with slotted pipe at just above mid depth of trash to just below bottom of trash depending on the depth to groundwater. The shallow probe will monitor the LFG migration that would cause surface emissions and LFG that would impact structures. The deep probe would monitor the migration of LFG that would impact groundwater. The 5 to 10 foot overlap at the mid-trash level would assist in determining if LFG is migrating from the mid-range of the landfill by indicating LFG in both probes. This could also indicate LFG is migrating the full depth of the refuse.

Vacuum Influence on Probes

Perimeter probes are meant to monitor the static conditions around the landfill not the vacuum conditions. Currently, landfill operators have to monitor their perimeter probes at least once a month. The regulations used to state that a probe in the vacuum influence of a nearby gas collector is disqualified. But after reviewing monitoring records at several landfills many of the forms do not have a column for recording any pressure or vacuum readings. It could be assumed that these readings were not taken during the monitoring procedure. The new regulations state that if a probe is under a vacuum influence it will be evaluated by CalRecycle on a case by case basis. Some landfill operators have been known to install collectors in native soil outside the trash prism and adjacent to “hot” probes to pull the methane gas out of the impacted probes. These probes should be disqualified because they will not be able to monitor the migration of LFG outside the vacuum influence. A probe in the influence of a collector can be blind to LFG migrating only 10 feet away from the probe.

If the records indicate a probe that is close to the limits of trash and yet a zero methane reading is recorded in all the chambers, then it may be in the vacuum influence of a nearby collector and the probe should be tested for vacuum influence.

Back Flow Prevention

PPT Profile investigations have identified another cause of impacted probes and groundwater. Based on PPT information, it has been discovered that collectors that are installed on the perimeter of landfills to control LFG migration are not high producing gas collectors due to the thinness of the refuse layers. Their main function is to collect low quality gas that could otherwise migrate offsite. However, when the flare or power plant is shut down, the header can become pressurized from the high-producing collectors in the center of the landfill. The LFG is then injected into the low producing perimeter collectors allowing the LFG to migrate to the probe and possibly to the groundwater. This is another reason why perimeter probes should not be in the zone of vacuum influence of collectors. When you consider that the LFG pressure in the header could increase to 50+ psi and when the vacuum is re-established the LFG will be extracted at only about 1 to 2 psi. This indicates that not very much of the LFG that was injected into the surrounding formation is recovered.

One way to address this problem is to turn off the valves to the perimeter collectors prior to shutting down the vacuum system. This works well for planned shut downs but sometimes the vacuum systems go down in the middle of the night and it is difficult to close valves on a dark landfill. There is also the time consuming problem of resetting the valves when the system is back on line. A better alternative is to install check valves on all perimeter collectors, which will prevent gas from entering the collectors and impacting probes or the groundwater during vacuum system shutdowns. Another advantage of the check valve is that it retains the gas in the landfill and will assist in restarting flares and generators. Check valves will reduce violations by about 60 percent.

Pre-Qualify Probe Locations

The PPT Landfill Profiling method has made several discoveries with the advantages of in-situ investigations inside landfills. The PPT can also be used to qualify a potential probe location prior to installing the probe. Once a preliminary location has been selected for a probe, a PPT sounding may have to be performed inside the landfill to determine the depth of trash. If the depth is known, then only the probe location would be tested. The PPT will be able to identify the various soil types, their density and locate the more porous layers that will transmit LFG faster. If the pore pressure transducer detects vacuum, gas pressure or a perched water layer in this location, consideration should be given to changing the location thereby, saving the cost of installing a probe in the wrong location. Following a PPT sounding and if the location is found to be clear of vacuum, gas pressure and perched water, the PPT rig can push in slotted steel pipe or install PVC pipe to the determined depths. The PPT can install these probes at a fraction of the cost of drilling and no cuttings are produced. Many landfills are surrounded by alluvial deposits, weathered bedrock or fractured bedrock.

The PPT rig can apply 20 tons of force on a 15 square centimeter tip and can penetrate most alluvial deposits and weathered bedrock. If fractured bedrock is encountered, the chances of intersecting a fracture that can transmit LFG using drilling techniques is very remote and a waste of time and money. The actual amount of fracturing in the bedrock should be considered in the decision tree, as to the effectiveness of placing a probe in this type of location. The PPT will locate the most practical locations for perimeter probes.

Conclusions

The RWQCB requires groundwater monitoring wells to monitor any impacts to the groundwater. Routine monitoring of perimeter probes should be added to the groundwater monitoring requirements to give enough warning to the potential impacts to the groundwater and allow time to intercept the migrating LFG. Currently, perimeter probes are allowed to be hundreds of feet from the landfill at the property limit. However, the groundwater may only be 25 feet or so from the bottom of the refuse. This means LFG can contact the groundwater years before it reaches the perimeter probes. Therefore, some probes should be place no further than the distance to the groundwater mainly on the down gradient from the landfill.

It is much more cost effective to use the PPT to locate pathways of migrating gas before the groundwater is impacted, than it is to pump and treat groundwater after it has been contaminated. If groundwater has already been impacted the PPT rig can be used with the hydro-punch type devices to take discreet groundwater samples to measure the extent of the contamination without installing expensive water wells.

By reducing the thickness of the Bentonite seals this will allow the seals to desiccate, crack and leak that much faster. The dry weather of California does not allow any moisture to migrate down to the seals and rehydrate them. There should be a procedure to allow water to be injected down the probes and the water pushed out by nitrogen to rehydrate the seals and also keep them at 5 feet thick at least. This will also help to clear the screens.

Due to the probe construction and monitoring shortcomings discussed, it is possible that there are many more landfills with migrating LFG and at higher concentrations then what are being presently reported. With the use of the Integrity Test and PPT technology with its in-situ capabilities, landfill engineering and compliance can be significantly improved. | WA

Reg Renaud is president of STI Engineering, Inc. (Silverado, CA) and has been involved in the geotechnical and environmental industry for 37 years. He can be reached at (714) 649-4422 or visit www.Airspacerecovery.com.

References

Environmental Protection Agency, CFR Title 40 Part 257, 258.23

California Department of Resources Recycling and Recovery (CalRecycle): CalRecycle.CA.GOV

www.calrecycle.ca.gov/SWFacilities/Landfills/Gas/Monitoring/Screening