When evaluating alternative daily cover for your landfill, consider the permeability of the proposed material, especially in areas with significant rainfall.

By J.D. Mohr and Mark Cadwallader

Today, landfills are more concerned than ever with mitigating odors and reducing the generation of leachate. There are various “upstream” measures that can be taken to manage rainwater runoff to suppress leachate production. A few of these measures are as follows: grading runoff to perimeter storm water ditches, temporary swales, berms and down chutes, shedding lifts to outside slopes, installing caps and covers, ADC selection, etc. For our purposes, I will examine a study performed by Mark Cadwallader of CTS on how a non-reusable geosynthetic ADC film performs as a fluid barrier versus soil and green waste on the working face.

Test Pad Construction

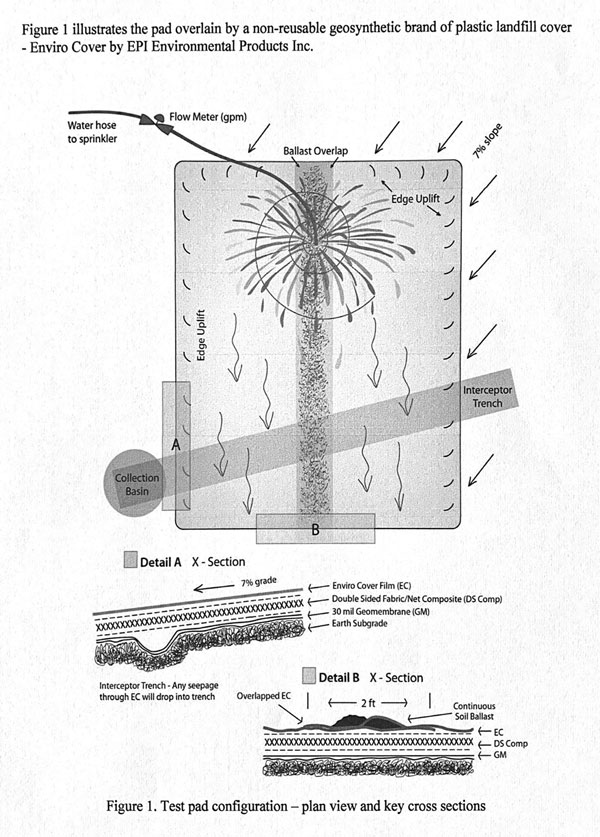

A (30 ft. x 35 ft.) test pad was installed lengthwise down a 7 percent slope. The pad consisted of a 30mil (0.75 mm) polyethylene geomembrane overlain by a geotextile/geonet/geotextile double-sided drainage geo-composite. A (9 in x 9 in) “flow interceptor trench” was cut at an angle in the soil beneath the geomembrane across the width of the pad at 90 percent of the distance downslope (see Figure 1, page 60) (Cadwallader, 2014).

Rainfall Simulation

A sprinkler connected to an inline flow meter measured the flow rate of the simulated rain event. All water spray remained on the pad in the calculated area. Penetrating measurements of the simulated rain event were collected in a graduated container at the end of the trench. The different daily covers tested were subjected to a simulated rainfall of 1.6 inches per hour to break through the cover and start to flow into the trench. Once the cover was saturated with water, breakthrough occurred at a relatively stabilized flow rate. Results shown in Table 1 (Cadwallader, 2014).

Enviro Cover Test (Non-Reusable Geosynthetic Film)

The Enviro Cover 1.75 mil film panels were deployed on the geocomposite pad parallel to the slope direction, just as they would be on the active area at the landfill. A sandy soil ballast was used to anchor the film and create a seal where the film overlaps. The water began to flow into the trench about 17.5 minutes after the simulated rain event at a rate of 0.105 gpm (U.S. gallons/minute). Only 3 percent of the total simulated rainfall penetrated the non-reusable geosynthetic film.

Green Waste Test

Approximately 6 inches of green waste (pine mulch) was placed over the test pad to receive the simulated rainfall event. The green waste was dry, although no moisture testing was conducted. The green waste absorbed a significant amount of rainfall before saturation and started flowing 44 minutes after the rainfall started at a rate of 3.4 gpm. The rainfall penetrated the green waste at nearly 100 percent (see Table 1) (Cadwallader, 2014)

Soil Test

Approximately 6 inches of a silty sand soil cover was placed over the testing area. The soil was dry during placement. The soil absorbed some rainfall, but also shed some with visible soil erosion at the runoff. The breakthrough was after about 20 minutes with the soil at 1.1 gpm flow. The rainfall penetration was measured at roughly 32 (see Table 1) (Cadwallader, 2014) This is better than green waste but significantly less effective than the non-reusable geosynthetic as a fluid barrier.

What About Foams and Slurries?

While not tested in this study, one would expect foams and slurries to perform similarly to green waste as these are more permeable materials. Once the foam or slurry saturates and dissipates, there will most likely be 100 percent penetration.

What About Tarps?

Geosynthetic tarps come in two classifications: reusable and non-reusable. The reusable tarps are thicker and pulled over the working face each day. They are removed from the working face at the start of each day before trucks may unload. A non-reusable geosynthetic is buried in the working face and requires no retrieval; the trucks will dump on top of the film with the next day’s waste.

Figure courtesy of Cadwallader Technical Services.

An advantage of a non-reusable geosynthetic is that it continues to provide barrier benefits to the next day’s fill sequence. Reusable tarps provide good barrier action against fluid migration only while in place. They are typically only applied for a partial day as they are deployed at the end of the day and retrieved first thing in the morning. Assuming a 12-hour workday, this would only provide half coverage on a 24-hour day with the waste being uncovered for half a day. This would mean the average reusable tarp provides exposure to precipitation for leachate generation with a penetration rate of 50 percent in the working face. In effect, reusable tarps offer less leachate penetration resistance than any of the other materials tested in the study.

Conclusions

When evaluating alternative daily cover for your landfill, consider the permeability of the proposed material, especially in areas with significant rainfall. The more rainfall infiltration you have, the greater opportunity there will be for gas and odor production as well. Porous materials such as green waste provide almost no fluid barrier between the environment and the waste. Reusable tarps provide a good barrier, but are only in place about 50 percent of the time leaving your working area exposed the other 50 percent. Soil provides some barrier, but the goal of ADC is to not use soil so you may conserve airspace. If your site is experiencing odor issues or is trying to reduce leachate generation, you may want to investigate using a non-reusable geosynthetic film. The economic benefits due to leachate reduction might justify the switch. | WA

J.D. Mohr is Business Development Executive for EPI Enviro Cover (Lynden, WA). He lives in Carmel, IN with his wife Sara, and two children. He has more than 16 years in the waste industry as a business owner and waste industry consultant. J.D. can be reached at (317) 316-2922, e-mail [email protected] or visit www.envirocoversystem.com.

Mark Cadwallader is Principal for Cadwallader Technical Services (Conroe, TX). He is the former Director of Research and Technical Development at Gundle Lining Systems. He is equipped to handle a wide variety of projects in the geosynthetics/geotechnical arena—from failure analysis to product development. Mark can be reached at [email protected].