Lighting comes in many shapes, sizes, lighting patterns and messages and is made to be fitted on most trucks and can be attached to the collection workers’ apparel. This would create a better awareness of waste collection workers in high motor traffic areas.

By Bruce J. Clark, PE

Solid waste collectors continue to die at an alarming pace across the U.S. This article focuses on the safety of workers that work the back of refuse trucks. These workers have to constantly leave the tailgate to collect the waste, exposing them to being struck by moving traffic. Motorists can have a lot of distractions and are rarely focused on the waste truck or collector.

Vehicle Lighting

Other professions have service vehicles that contain supplemental lights that make the vehicle more visible to motorists. This includes the police and fire, of course, but also tow trucks, utility trucks, snowplows, construction trucks, school buses and municipal buses. So, what happened to refuse trucks?

Take a look at these photographs comparing the lighting visibility at dark and low light of different vehicles types (see Figure 1). Some, but not all, of the refuse trucks do not seem to have the same array of lights as the others; for example, no flashing yellow lighting, no lights along the sides, no movable lights as with a school bus. This does not imply that every refuse truck may not have enough lighting for good visibility; however, I think some could use much more supplemental lighting to increase visibility.

Now, compare those in Figure 1 to the waste collection trucks in Figure 2. These waste collection trucks are not lit as well, in my opinion, as when you consider those in Figure 1 use colored, flashing lights in multiple positions on the vehicle to attract attention.

Why are garbage trucks not lit up like Christmas when this could increase worker safety? There could be several answers; the state or federal transportation regulations do not allow it, budget allocations are not adequate, departments are not familiar with the variety of lighting available and others. Assume for a moment, that none of these were barriers.

Extra safety illumination lights and messaging devices on refuse collection trucks do not appear to be universal. (Again, suspend for a moment any regulations that currently might prohibit certain types of supplemental lighting.) Figure 3, page 50, is an example of a basic refuse truck. Notice there are no extra lights of any kind. We suggest that trucks like this could be modified to be more attention-getting as it relates to alerting drivers to the workers. For example, there are exterior message boards that can be mounted on the front and rear of the truck and controlled by the driver that can indicate hundreds of lighted, programmable messages shown. Messages can be programmed to be static, moving or flashing. A message board combined with bright flashing strobe lights really ups the ability to get driver’s attention.

There are more possibilities. We have all probably seen a school bus when they come to a stop—an arm with a big red STOP sign on it swings out to alert moving traffic. Why not adopt that same technique to a refuse collection truck? Swing-out signs could be mounted on both sides, and instead of indicating STOP, which likely is not legal, the sign could be modified to indicate, “WORKERS SLOW” and the color changed to yellow (if red is not legal), and the shape to a diamond (i.e., a Yield sign). The sign also should have flashing colored lights and at least one, if not two, high intensity, flashing strobe lights. So, we have combined a warning device with movement and illumination to attract motorist’s attention (see Figures 4 and 5). And given the fact that refuse trucks make hundreds of stops per day, the swinging assembly will have to be designed to be very stout for the much higher wear and tear than a school bus swing sign.

Worker Lighting

If we used safety tools from other industries with similar worker safety problems and incorporated them into the waste collection business, could we reduce the number of fatalities? We cannot control the actions of a worker, but we can help them be more noticeable to the drivers of the passing vehicles.

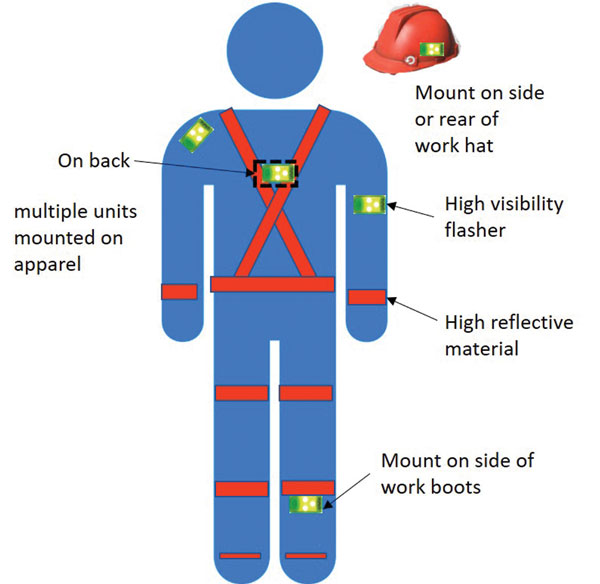

For example, I have not seen the universal use of flashing strobe safety light devices—generally used by the towing industries and utility workers. These are mounted on the worker’s apparel with a clip or strap (see Figure 6). They can provide very bright, flashing colored lights that can attract a driver’s attention. These should be located in various areas of the body where they will not be covered; for example, on the forearm, on the chest or even on a pull-over boot. Fitness companies have swung into action for their customers and provided colored safety strobe lights that can be attached to apparel, including, lighted (and flashing light) vests, shoes, shirts, pants (waist), arms and on caps (see Figure 7).

The cycling industry has also done a lot of study of lighting to reduce bike and car crashes. Like the waste industry, the biking industry experience accidents in daylight as well as low light hours. Eighty percent of biking crashes happen in daylight. Studies show reductions of 19 percent when bikes use so-called “daytime running lights” (DRL). The auto industry found a reduction of up to 28 percent when one car had DRLs and the other did not.

The DRL is different than a regular light. The light is designed with a special flashing pattern, a wide visibility range (some up to a 360-degree arc), lighting intensity and pattern that can be varied, and the lighting is purposely much brighter (visible up to a 1/4 mile), to catch awareness and be seen in daylight. The lights could be mounted on worker clothing or the truck (see Figures 8 and 9, page 52). A cycling company called SeeSense has a patented unit equipped with sensors and artificial intelligence that flash brighter and faster at road junctions and high traffic urban areas, where most cycling crashes occur.

Trek, a progressive bike company, asked Clemson University to do a study on what could help cyclists be seen better and reduce accident rates. The University came back with three clear recommendations—first, for DRLs, secondly, clothing that highlighted moving parts (shoes, overshoes, gloves, arm warmers), and third, choosing bike gear that contrasts with the environment. Both a cyclist and a collection worker deal with traffic and have to be seen to survive, so, I believe these recommendations would be applicable to the waste industry as well.

Bontrager, a Trek company, claims that a flashing light is 1.4 times more effective than a steady beam. While most lights use a flashing pattern, its day flash mode has been created specifically to make the beam more noticeable by varying outputs on an interruptive flash pattern.

Lastly, collection crews should consider donning high-visibility clothing, including on the upper torso, arms and legs. Some manufacturers produce shorts with high visibility components for hot weather regions. Biomotion studies have shown that areas of the body with the most movement— the ankles and wrists—are key areas to also provide reflective surfaces on.

Learning from Other Industries

Lighting comes in many shapes, sizes, lighting patterns and messages, is made to be fitted on most trucks and can be attached to the collection workers apparel. While the cycling industry advocates DRLs, clothing that highlights moving parts of arms, legs, etc., and high visibility clothing can reduce cycling/car collisions, other professions like the police, utility workers and the towing industry, where workers are exposed to traffic hazards, have incorporated high visibility safety lighting and message boards for their vehicles to reduce traffic fatalities. In both cases, the waste collection industry could follow suit, especially if transportation regulations allow and use supplemental safety lighting and message boards for their trucks. This would create a better awareness of waste collection workers in high motor traffic areas and can be increased with supplemental, specialized safety lighting. | WA

Bruce J. Clark, PE, is a consulting engineer who has worked with the solid waste industry for more than 30 years. He is a manager in Tampa, FL for Wood Plc and can be reached at (813) 326-3498 or e-mail [email protected].