Lessons learned from the project implementation team for the Hillsborough Resource Recovery Facility.

By Marc J. Rogoff and Warren N. Smith

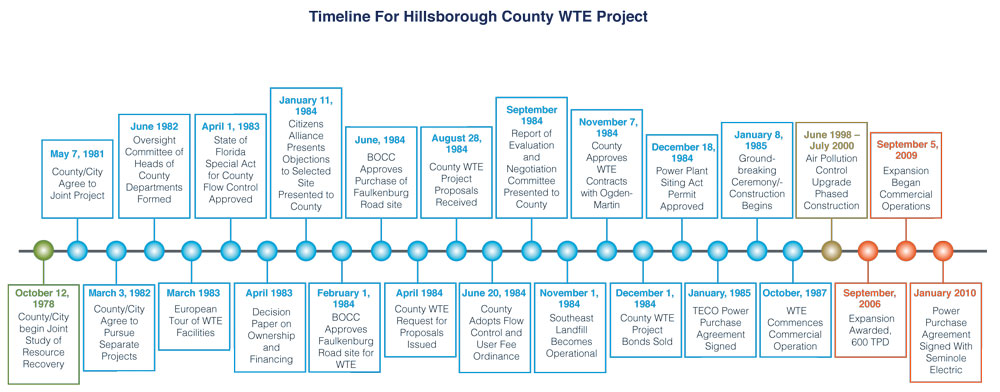

The March 2020 issue of Waste Advantage Magazine included discussion of the trials and tribulations impacting Hillsborough County’s (FL) WTE project. We continue this issue with an overview of how the project was implemented and the many decision steps.

Reaffirmation of Project Site Selection

One of the first milestones we needed to accomplish was to again hold the public hearing for the selection of the project site. The major public opposition group lobbied with the Board of County Commissioners (BOCC) to hold another public hearing since they argued, that with three of the previous Commissioners now removed from office,1 the previous Board’s decision was tainted and, thus, the site selection decision was tainted. This time our hearing lasted eight hours and included the opposition groups arguing again that the WTE facility would eliminate development within the I-75 corridor. The BOCC decided otherwise and voted 5-0 to continue with the development of the WTE project at the selected (Faulkenburg Road) site. They did direct the Project Team to include representatives of the Brandon Chamber of Commerce to help develop the landscaping requirements for the project in the RFP.

“Kick the Tires” Road Trip

At that time, the County’s WTE project would be the largest public bond issue ever issued by Hillsborough County government. The County had issued public bonds for more typical projects like parks and recreation programs and water and wastewater utilities, which were the types of public projects that were well understood by the BOCC and the public. For WTE, we would be asking the public to finance a very expensive project with a technology not generally used in the U.S. at that time. While it was true that neighboring Pinellas County had started construction of their new WTE plant, our Commissioners wanted a team of County staff and consultants to “kick the tires” of operating WTE plants in Europe to be certain that the best decisions were being made.

We organized an extensive tour of a dozen WTE plants in six Western European countries (Denmark, Germany, Switzerland, France, Belgium and Holland), which included all the major prospective European suppliers of WTE technology (Volund, Steinmueller, Martin, Von Roll, and Katy Segers) at the time. The participants on the tour included a County Commissioner, the County Attorney, the President of the Brandon Chamber of Commerce, a member of our Bond Underwriter team, project consultants Camp, Dresser and McKee and department staff. Going by private bus, we were able to tour the plants, visit with the technology providers, and interview plant operators and nearby businesses. This allowed our team to develop ideas on how the County’s plant could be designed to be as compatible as possible with nearby commercial developments. Architectural compatibility was made an important element of the RFP. This resulted in the winning proposal providing such project features as the coloring of the building and stack (blue), enhanced landscaping of the site, and enhancing the exterior skin of the building (with brick accents and translucent siding) to give it the appearance of an office building.

Project Decision Points

With the help of CDM, various Decision Papers were developed over the course of six months including project recommendations such as technology, facility ownership and operation. The BOCC eventually voted that the WTE plant would use mass burn technology, and would be owned and financed by the County, but operated by a private company, creating a public-private partnership. Another Decision Paper recommended initial development of a 1,200 ton per day plant with three 400 ton per day boiler trains, but with built in expansion features to accommodate a fourth boiler train (tipping floor, pit and cranes large enough for the additional boiler and a fourth flue in the stack). The BOCC accepted this recommendation. At that time, Hillsborough was one of the fastest growing counties in the country and there was a concern that the WTE could be expanded in order to continue to minimize landfilling in the future.

With these major plant sizing and operational issues decided, CDM began work on permitting the proposed WTE facility. Based upon the Decision Paper on Environmental Regulatory Review it was decided to use the Electrical Power Plant Siting Act (PPSA) to streamline and consolidate the regulatory process and the many legal hurdles that would to be resolved on the local, regional, state and federal levels.

Public Education and Involvement

While we were providing status reports on the project to the BOCC from the very beginning, our efforts ramped up as soon as we returned from our European tour. A project fact sheet was developed, along with a master slide (photo) set. More than 100 presentations on the project were made to civic, social, environmental and homeowner’s associations. We invited our opposition group to send representatives to sit on a landscaping committee to help prepare specifications to be included in our RFP. This active citizen involvement with the project helped minimize opposition, although there remained a small group that opposed the project even after facility construction began.

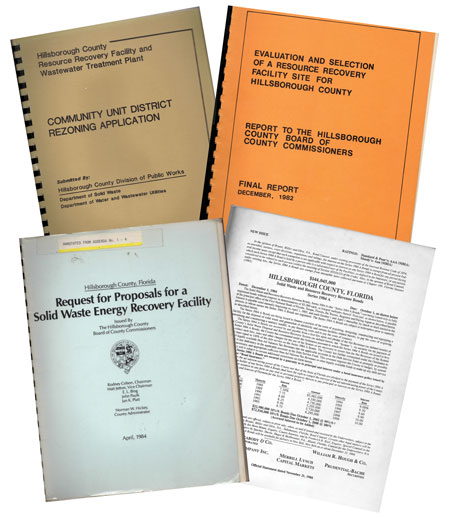

RFP and Construction

Issuing the RFP was one of the major final steps remaining to achieve project success. The BOCC had concurred at the outset that the project would be designed, constructed and operated by a private vendor. The RFP was crafted in a way that minimized ambiguities that might result in some proposers adding a risk factor to their ultimate bid price for the WTE facility. Additionally, the RFP contained minimum technical and financial qualifications that each proposer had to meet in order to prevent an unqualified contractor submitting a very low price in order to be selected.

At the same time, the Project Team was proceeding to secure a signed electrical sales agreement with the local utility (Tampa Electric Company), a project site with all the regulatory approvals, and nearly all of the air emissions and environmental approvals by the State and the Cabinet under their Electrical Power Plant Siting Act (PPSA). We also began the process of the financing for the project by hiring a financial advisor, bond counsel and team of investment bankers who were able to secure a major portion of the State’s pool of industrial development bonds (IDBs). The RFP included the following major aspects:

• An overview of the County’s team and implementation process

• General information about the County

• Detailed instructions for proposal preparation and submission

• Technical requirement for the facility

• Proposal forms for pricing, performance guarantees, equipment specification and utility use

• Draft design and construction agreement, and draft operation and management agreement

• Evaluation, selection and negotiation process

What differentiated our RFP from other similar WTE procurements was that the site was owned and properly zoned, the major environmental permits were in the process of being obtained, and the supply of waste had been secured. Additionally, the need for the County to issue the bonds to finance the project prior to January 1985 (which was four months after proposals were to be received) was that new tax laws would go into effect restricting the arbitrage rules for IDBs. The financial advisor calculated that under the new rules it would cost the County an additional 20 million dollars. As such, our time for contract negotiation was limited so we included a scoring of the contract changes proposed by the proposers in terms of the time we thought it would take to come to a final negotiation.

On August 28, 1984, we received six proposals, four of which were deemed complete. Based on the scoring criteria established in the RFP, the Project Team ranked Ogden Martin (now Covanta) as the first ranked proposal and began active contract negotiations. After a detailed negotiation process, the BOCC selected Ogden Martin as the County’s vendor for the WTE project, and contracts were signed on November 7, 1984.

Permitting Approval

To expedite the overall project, permitting was initiated once the site was secured. Like other large power plants in the State, as mentioned above, we used the PPSA to help streamline permitting approvals on local, regional, state and federal levels. A comprehensive permit document, much like an environmental impact statement, was submitted to the Florida Department of Environmental Protection, which served as the coordinating agency under the PPSA. Our permitting attorney was able to secure consent agreements with most agencies, and the Governor and the State Cabinet approved the facility permit on December 18, 1984.

Financing

Once the agreements were signed with Ogden Martin, CDM was engaged to develop an Engineer’s Feasibility Statement for the eventual bond issue for the project. The Project Team worked with CDM in developing a compelling story of the project to our eventual bond investors and bond insurance companies. Presentations were made in New York to the bond rating agencies and favorable bond ratings of AAA (Standard & Poor’s) and Aaa (Moody’s) were obtained. The project went to market on December 1, 1984 and $144 million of project bonds were sold within 15 minutes!

Groundbreaking

With all the major project components now in place, a groundbreaking was scheduled on January 8, 1985. Plant construction went uneventfully over the next two years, with commercial plant startup achieved on April 1987. Increasing residential and commercial growth in the County required a 600 ton per day expansion, giving the expanded plant a design capacity of 1,800 tons per day, which became operational in September 2009.

In conclusion, the County’s WTE plant having been in operation now for 33 years, provides the following major assets to the County:

Combusts up to 1,800 tons of solid waste per day

Reduces the amount of material that is landfilled by 80 percent

Saves $500,000 per year in utility costs by providing electricity to County-owned buildings

Produces $450,000 in revenue per year by recovering and recycling metals

Generates up to 45.5 megawatts of electricity to the grid, equivalent to $16 million per year | WA

Marc Rogoff was the Resource Recovery Administrator for Hillsborough County, FL. Marc is now a Senior Consultant with Geosyntec Consultants (Boca Raton, FL) with their Solid Waste Advisory Practice. Marc can be reached at (813) 810-5547 or [email protected].

Warren Smith was the County’s Solid Waste Director. Warren is retired after having served as Director of Pinellas County’s Department of Solid Waste Operations and Solid Waste Manager for HDR Engineering, Inc. He can be reached at (727) 515-0006 or [email protected].

**The authors want to thank Paul Stoller for his review and comments on the content of this article. Paul served as CDM’s Project Manager on Hillsborough County’s WTE project and is now retired. The authors would also like to thank Kimberly Byer, Solid Waste Director, Hillsborough County, FL, for access to historic project documents.

Note

During the WTE site selection process, in early 1983, three out of the five County Commissioners were arrested and indicted for bribery and removed from office. In accordance with Florida law, the Governor of Florida appointed three people to fill out the remainder of those Commissioner’s terms of office. Those appointed all resided in Hillsborough County, had impressive backgrounds, were well respected in the community and had no political ambitions to continue as County Commissioners, and they were guided by making decisions that were in the best interest of the County.